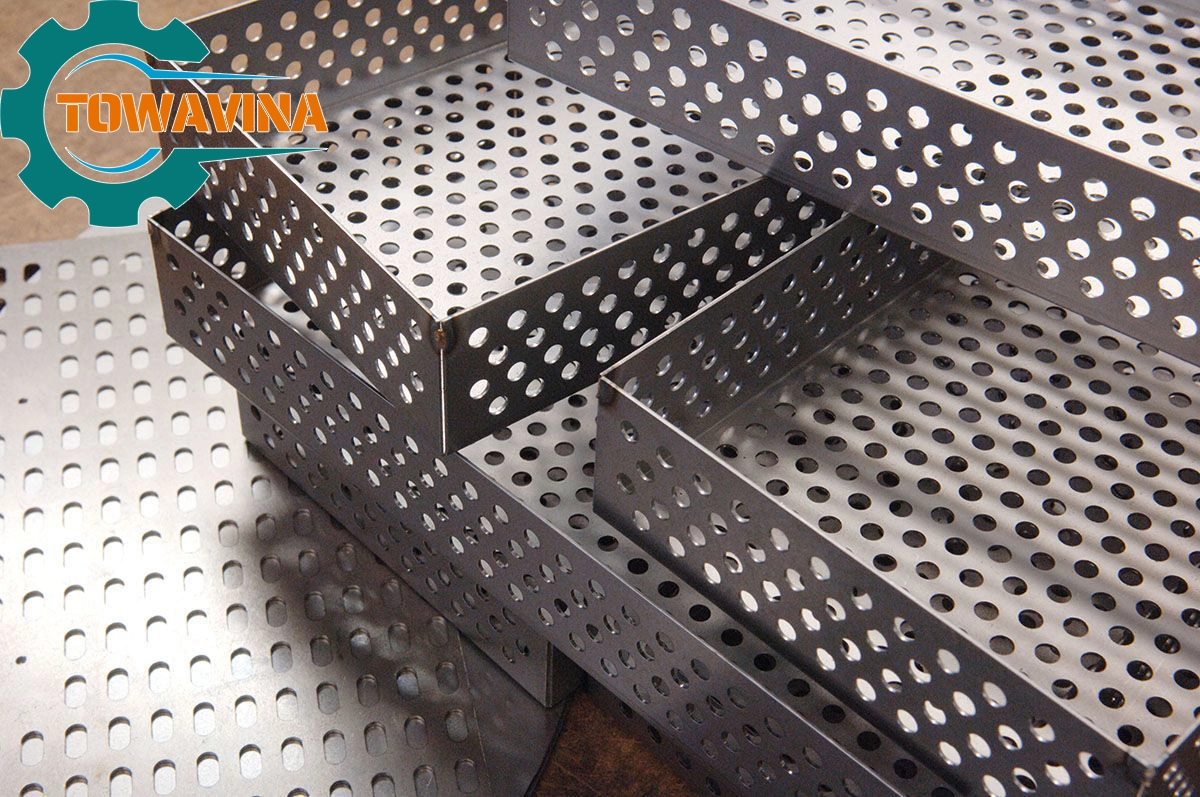

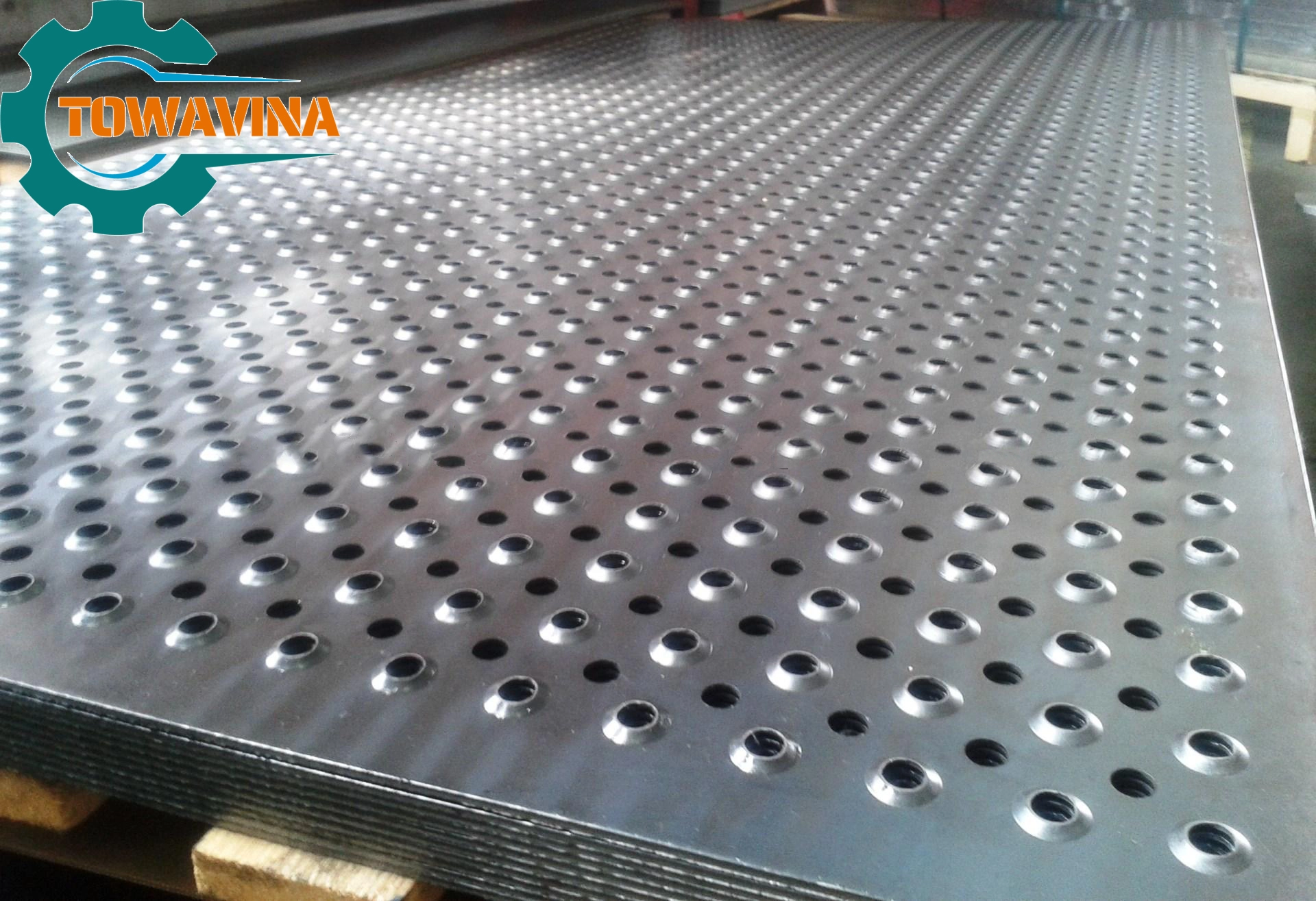

“Stainless Steel Stamping Machining is a crucial metalworking process in the industry, especially for creating varied shapes and functional stainless steel parts and products. This process utilizes pressure to transform and manufacture high-quality stainless steel components. Differential Stainless Steel Stamping products cater to numerous applications in fields like medical equipment, jewelry, interior design, and various other industries.

Advantages of Stainless Steel Stamping Machining

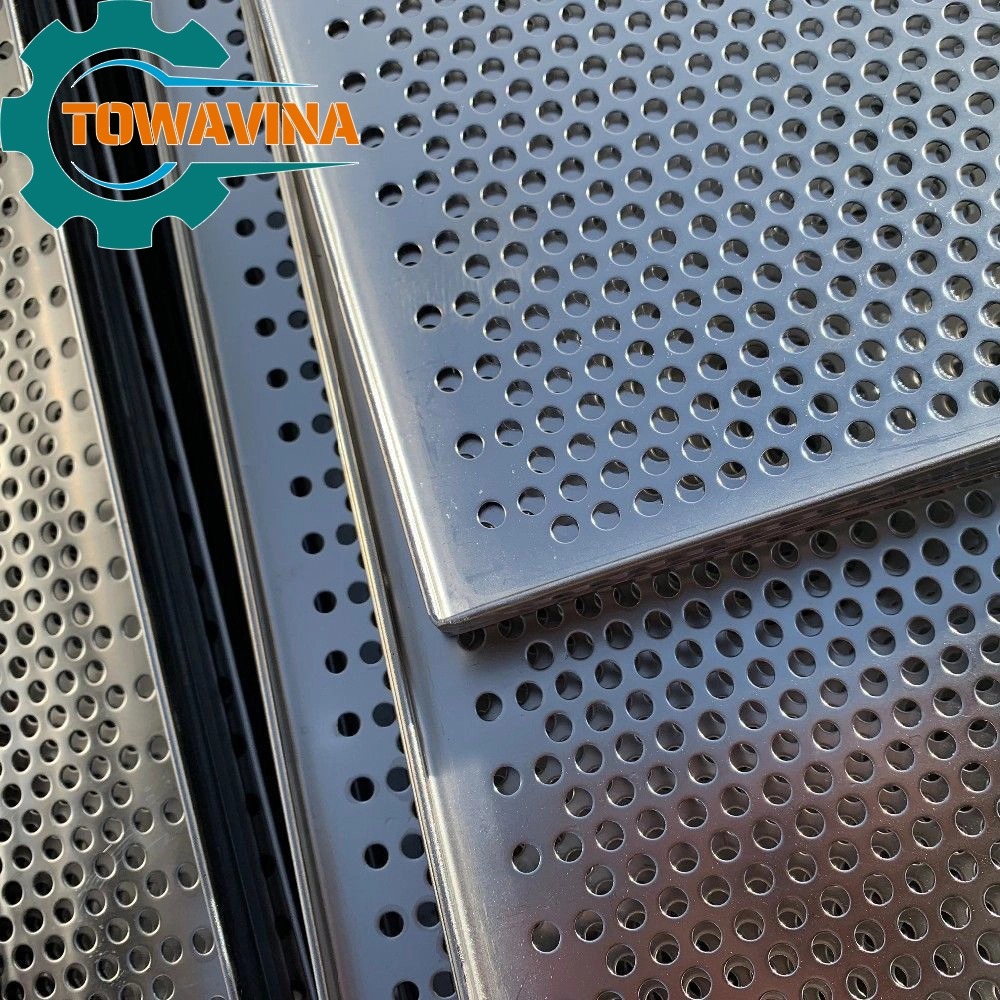

- Precision and Quality: Products from Stainless Steel Stamping Machining undergo an accurate stamping process, ensuring precision and high quality. These products often have smooth surfaces and a high gloss finish, suitable for applications that demand high aesthetics.

- Versatile Application: These products find application across various industries, from manufacturing sensitive medical components to producing shiny stainless steel jewelry. The differential stainless steel stamping process is adaptable to diverse specific applications.

- Time and Cost Efficiency: Stainless Steel Stamping Machining products utilize modern machinery and automation, optimizing the manufacturing process and reducing material waste, thus saving production costs.

- Capability for Complex Designs: The stainless steel stamping process allows for the creation of intricate designs and various curved details. This is particularly important in manufacturing stainless steel products that require creativity and complexity.

- Safety and Efficiency: Products from Stainless Steel Stamping Machining are computer-controlled, reducing the risk of human error and ensuring safety for employees during the manufacturing process. This translates to efficient and secure production.

Reviews

There are no reviews yet.