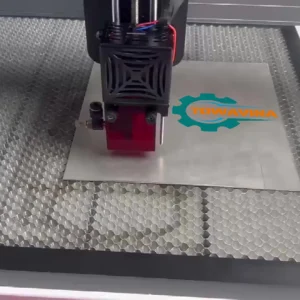

The “Detail Laser Cutting – Components” service plays a unique and effective role in metalworking, using laser cutting technology to produce precise and durable metal components and parts. This service provides the capability to manufacture intricate metal details that meet diverse design requirements and high-quality standards in various applications.

Advantages of Detail Laser Cutting – Components:

- Precision and Quality: This product utilizes advanced laser cutting technology to ensure high precision and superior quality for metal components. The resulting products often possess smooth surfaces, requiring minimal post-processing, thereby saving time and effort after fabrication.

- Capability to Create Complex Designs: Laser cutting technology enables the creation of intricate designs, small holes, and details that traditional cutting methods cannot achieve. This makes it suitable for applications demanding creative and complex design features.

- Production Flexibility: This product can cut various types of metals, from carbon steel to stainless steel and aluminum, offering ample opportunities in manufacturing diverse components.

- Time and Cost Efficiency: Laser cutting technology minimizes production time and material waste, optimizing manufacturing costs and increasing productivity.

- Safety and Efficiency: The “Detail Laser Cutting – Components” product is computer-controlled, reducing the risk of human error and ensuring safety for employees during the production process.

Reviews

There are no reviews yet.