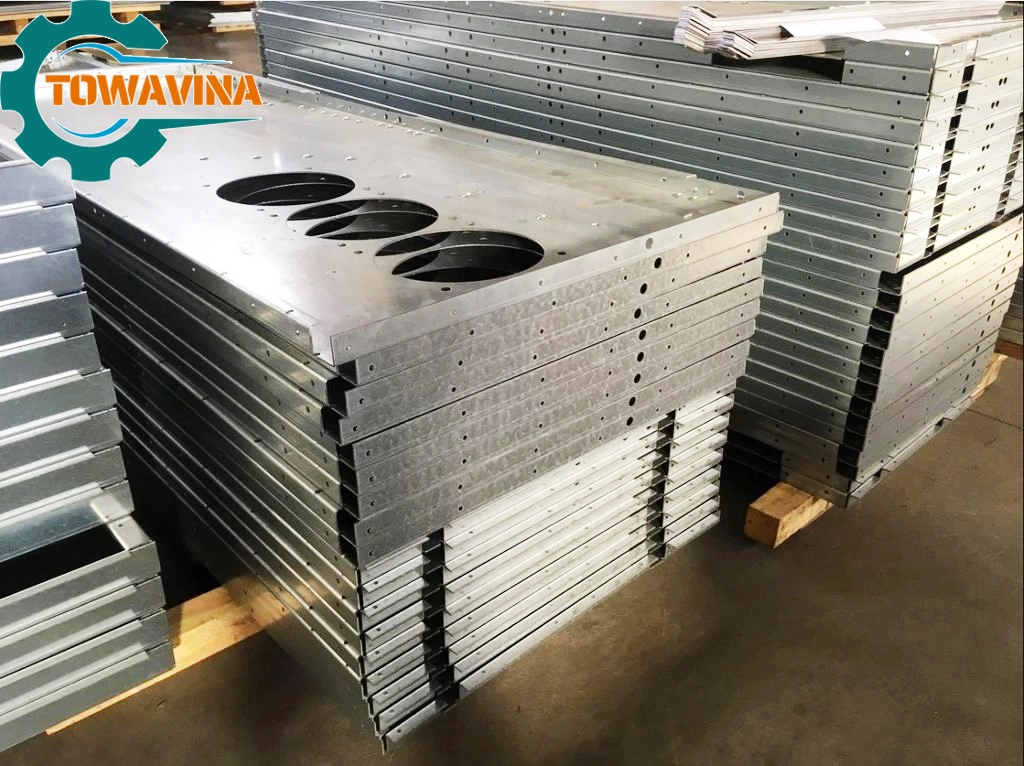

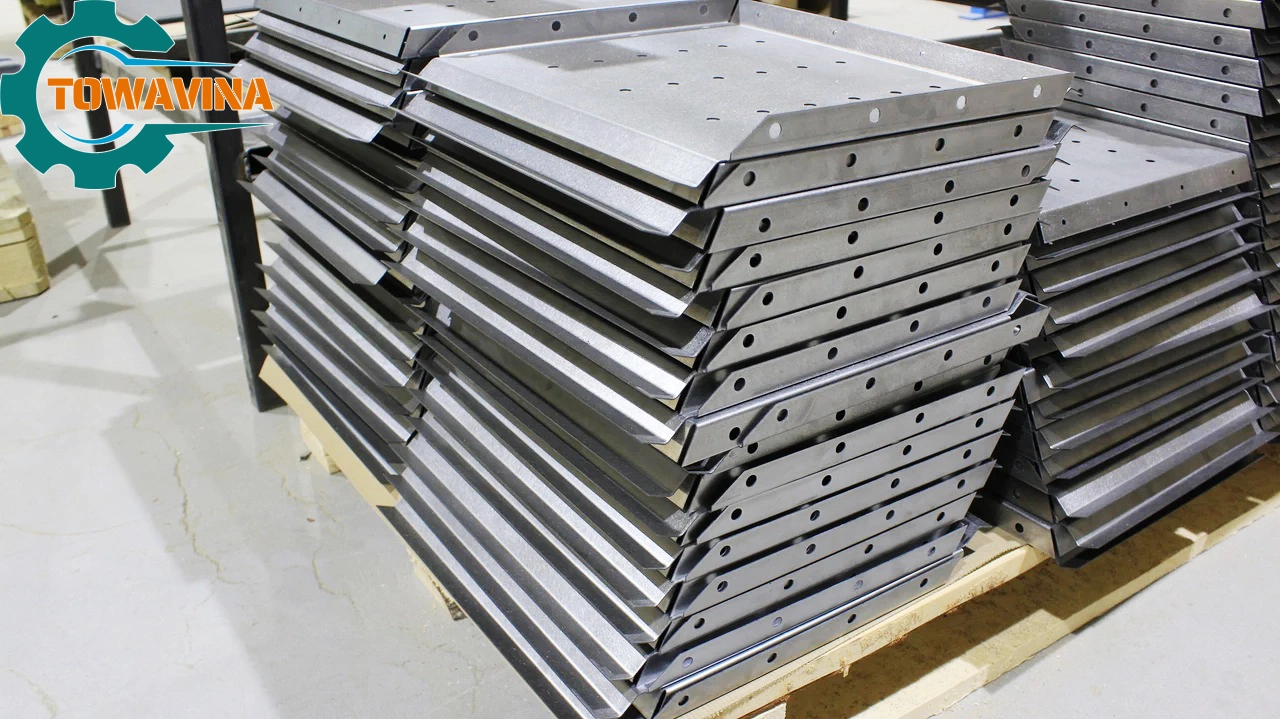

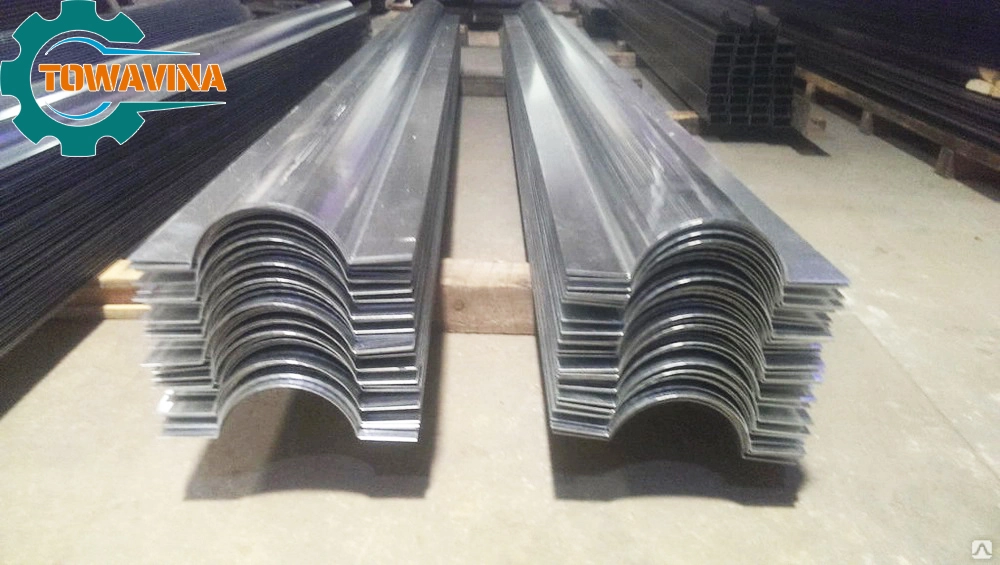

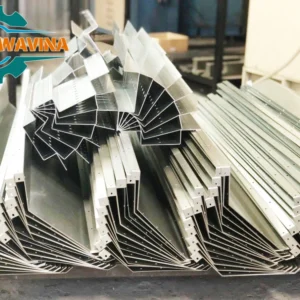

The “Steel Folding” process is a unique and crucial metalworking procedure within the metal industry. This method transforms steel sheets into components or products that are bent or folded according to specific design requirements. This product provides the ability to create steel components with high precision and remarkable durability, serving various applications from machinery manufacturing to construction and beyond.

Key Advantages of Steel CNC Press Brake Machining

- Precision and Durability: Steel Folding utilizes advanced technology to craft steel components with high accuracy, ensuring they meet stringent technical requirements. These products tend to exhibit superior durability, capable of withstanding prolonged loads and pressures.

- Manufacturing Flexibility: It has the capability to produce a diverse range of products and components, from small curved details to larger items. This adaptability caters to various custom applications across different industries.

- Folding Various Steel Types: This process can bend different types of steel, including carbon steel, stainless steel, and various steel alloys. This versatility opens up opportunities for producing diverse, customized products.

- Time and Cost Efficiency: The intelligent folding process minimizes production time and material waste, optimizing manufacturing costs and increasing overall productivity.

- Safety and Efficiency: Computer-controlled, Steel Folding minimizes the risk of human errors, ensuring a safe working environment for employees throughout the production process, thereby enhancing efficiency.

Steel CNC Press Brake Machining product not only ensures high-quality steel products but also streamlines manufacturing processes across various industries. Utilizing this product will assist in meeting precise and efficient steelworking needs.

Reviews

There are no reviews yet.