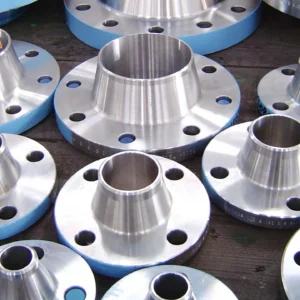

The advantages of CNC Turning Machining – Heat Treated Steel

- Quality and Precision: CNC Turning Machining – Heat Treated Steel utilizes advanced technologies to ensure the quality and precision of products. The resulting items often possess high durability and load-bearing capabilities, suitable for applications demanding high precision.

- Production Flexibility: This service can generate a wide range of products and components, from simple curved details to complex items. This versatility makes it suitable for various customized and diverse applications in the industry.

- Capability with Heat-Treated Steel Machining: This service can work with various types of heat-treated steel, including hot-rolled steel, cold-rolled steel, and heat-treated alloy steel. This opens up numerous opportunities for manufacturing diverse and customized steel products.

- Time and Cost Efficiency: The process of thermal processing steel machining is executed using modern automated machinery, minimizing material wastage and optimizing production time, thereby reducing manufacturing costs.

- Safety and Efficiency: CNC Turning Machining – Heat Treated Steel services are carried out by experienced professionals and computer-controlled systems, ensuring safety and efficiency throughout the heat-treated steel machining process.

CNC Turning Machining – Heat Treated Steel products not only ensure high-quality heat-treated steel products but also optimize production processes across various industries. Utilizing these products will help meet all heat-treated steel machining requirements accurately and effectively

Reviews

There are no reviews yet.