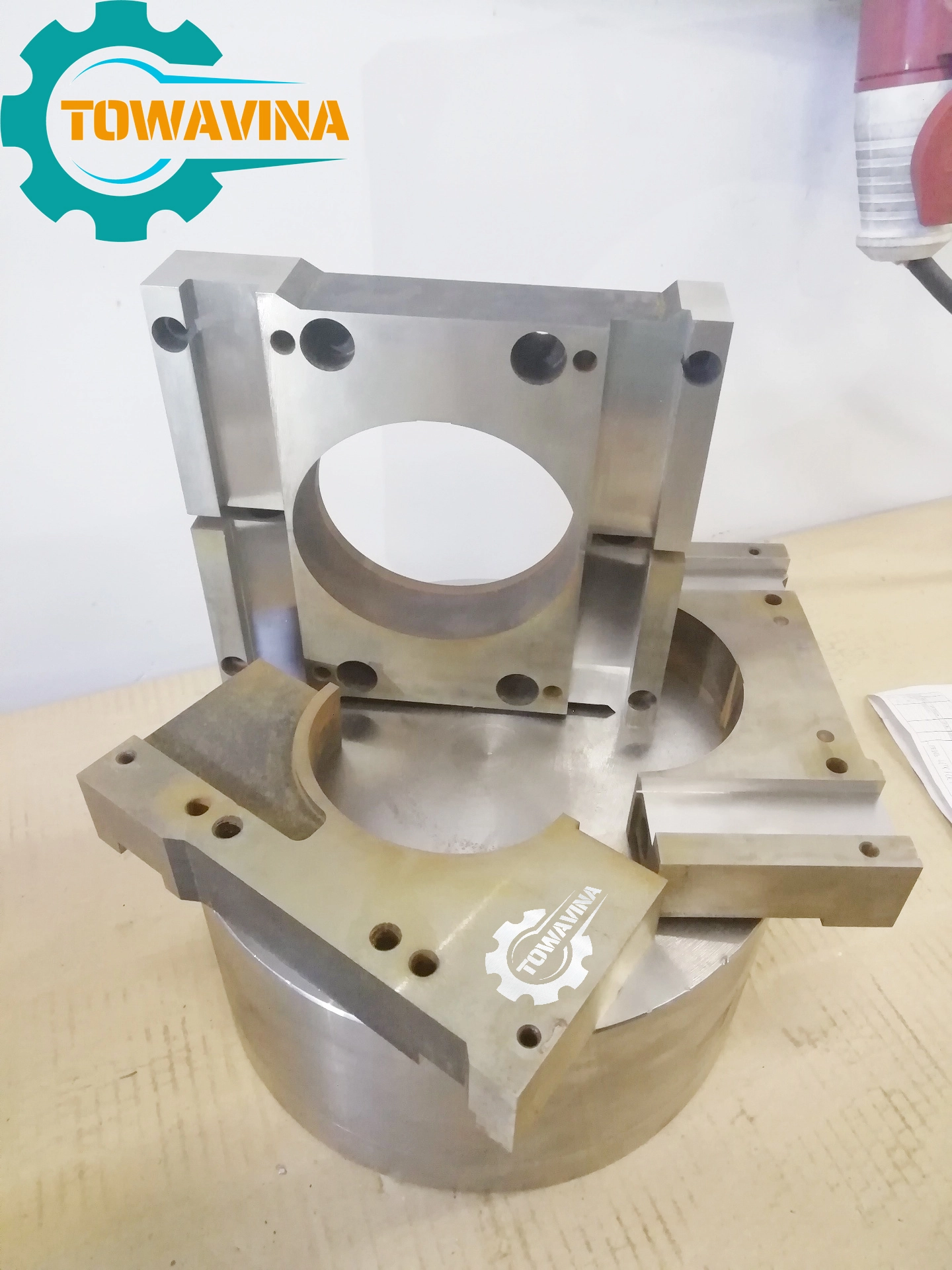

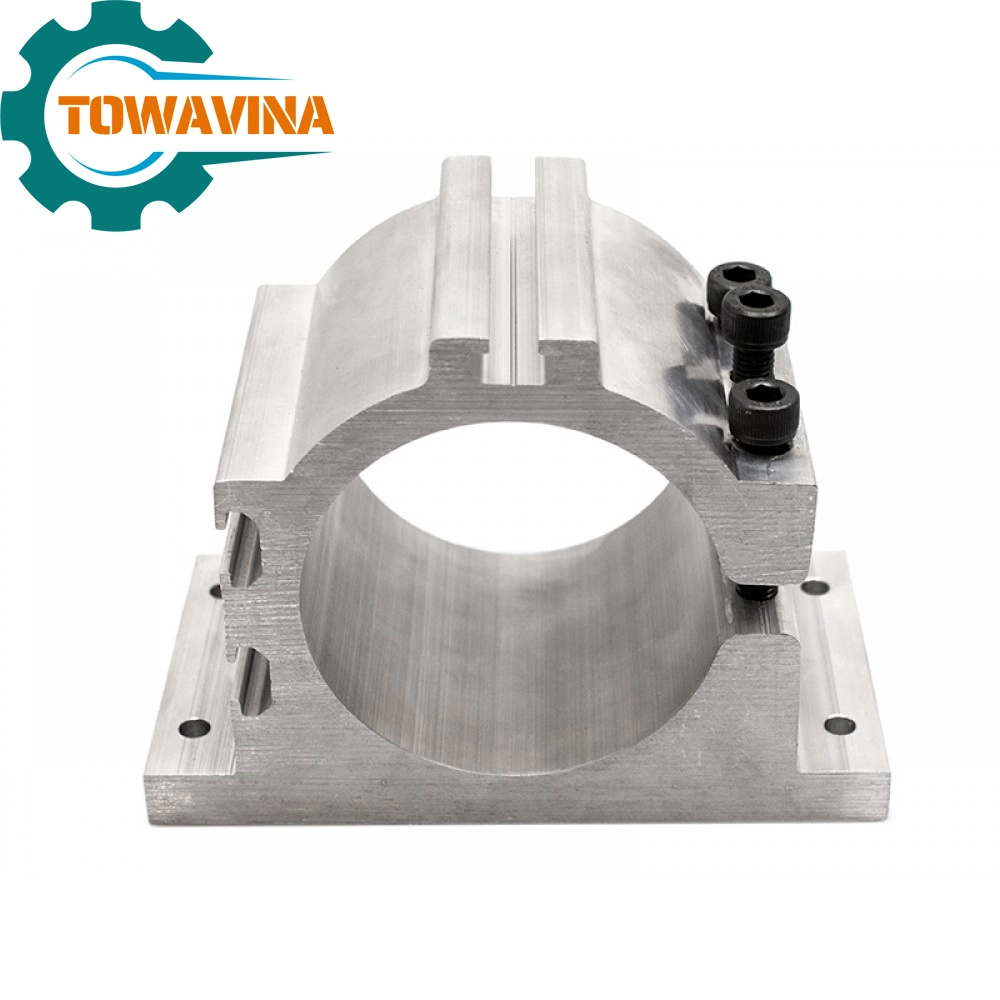

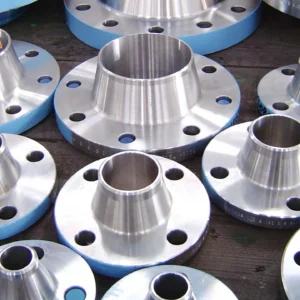

CNC Milling Machining Service for Machine Parts is a crucial process in the metalworking industry, utilized to craft machine parts with high precision and durability. This process employs advanced CNC milling machines to fabricate machine parts with a diverse range of shapes, sizes, and functionalities.

Advantages of CNC Milling Machining for Machine Parts

- Precision and Durability: The CNC Milling Machining Service for Machine Parts utilizes CNC milling technology to ensure precision and durability in machine parts. The resulting products often exhibit high durability and can withstand heavy loads and significant pressures, ideal for applications requiring mechanical integrity.

- Manufacturing Flexibility: This service excels in producing machine parts with diverse sizes and designs, from simple machine components to complex products with special functionalities.

- Processing Multiple Metal Types: This product has the capability to work with various metal types, including high-strength steel, aluminum, copper, stainless steel, and other metal alloys. This opens up numerous opportunities for manufacturing diverse and custom machine parts.

- Time and Cost Efficiency: The CNC milling machining process for machine parts is executed using modern automated machinery, minimizing material waste and optimizing production time, thus reducing manufacturing costs.

- Safety and Efficiency: Controlled by experienced professionals, the CNC Milling Machining Service for Machine Parts ensures safety and efficiency throughout the machining of machine parts.

The CNC Milling Machining Service for Machine Parts enables you to obtain high-quality machine parts that meet all requirements for manufacturing and machining machine components. Utilizing these products will help you create diverse and high-quality products, fostering the development and success of your business.

Reviews

There are no reviews yet.