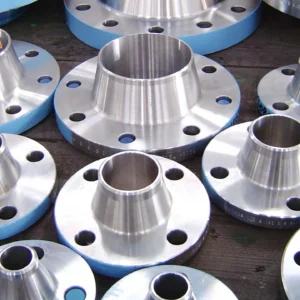

Machining services for gears, couplings and shafts represent a pivotal aspect within the metalworking and precision engineering industry, utilized in manufacturing gears, couplings, and shafts for various applications, from industrial machinery to automated equipment and transmission systems.

Advantages of Gear, Coupling and Shaft Machining

- Precision and Durability: This service employs precise metalworking and engineering technology to ensure the accuracy and durability of gears, couplings, and shafts. The resulting products often exhibit high durability and can withstand heavy loads and significant pressures, ideal for applications demanding mechanical integrity.

- Manufacturing Flexibility: This service showcases the capability to produce gears, couplings, and shafts with diverse sizes, designs, and functionalities, ranging from standard products to custom-made ones.

- Processing Multiple Metal Types: These products have the ability to work with various metal types, including carbon steel, metal alloys, aluminum, copper, and other metal varieties. This opens numerous opportunities for manufacturing a wide range of gears, couplings, and shafts.

- Time and Cost Efficiency: The gear, coupling, and shaft machining process is carried out using modern automated machinery, reducing material waste and optimizing production time, resulting in cost savings during manufacturing.

- Safety and Effectiveness: The Gear, Coupling, and Shaft Machining Service is controlled by experienced professionals, ensuring safety and efficiency throughout the machining process.

The machining of gears, couplings and shafts enables the production of high-quality mechanical products that meet diverse requirements for manufacturing and supplying these components for various applications. Utilizing these products will help you create diverse and high-quality items, fostering the development and success of your business.

Reviews

There are no reviews yet.