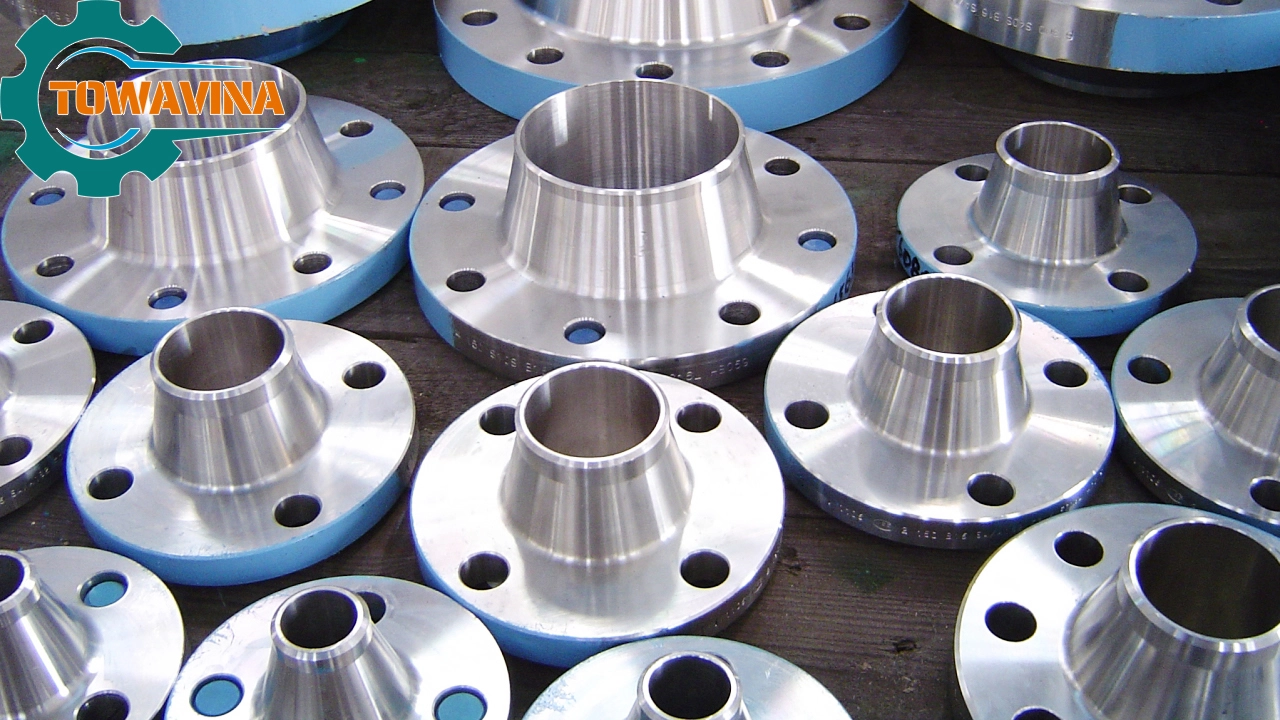

CNC Turning Machining – Flange services play a crucial role in the metalworking and machinery industry, especially in machining flange faces. This process involves the use of industrial lathes to machine and refine flange faces, which can be used in various applications, from the oil and gas industry to manufacturing heat treatment equipment.

Advantages of CNC Turning Machining – Flange

- Precision and Durability: CNC Turning Machining – Flange services use modern industrial lathes to ensure precision and durability of flange faces. Products created through this process often exhibit high durability and the ability to withstand significant loads and pressures.

- Production Flexibility: This service has the capability to create flange faces with diverse sizes and designs, from standard flange faces to customized products. This versatility makes it suitable for various applications and different types of flange faces.

- Ability to Machine Various Metals: This product has the capability to machine various types of metals, including carbon steel, stainless steel, aluminum, and other metal alloy types. This opens up numerous opportunities for manufacturing diverse and customized flange faces.

- Time and Cost Efficiency: The process of machining flange faces is executed using modern automated machinery, minimizing material wastage and optimizing production time, thereby reducing manufacturing costs.

- Safety and Efficiency: CNC Turning Machining – Flange services are carried out by experienced professionals, ensuring safety and efficiency throughout the flange face machining process.

CNC Turning Machining – Flange play a vital role in producing high-quality and efficient flange faces, meeting various requirements across multiple industries. Utilizing these products will provide you with high-quality flange faces and components to drive the development and success of your business.

Reviews

There are no reviews yet.