Laser Metal Cutting Method

Laser metal cutting technology is becoming increasingly popular in the current industrial landscape. Utilizing a laser beam with short wavelengths and high energy, this method excels in crafting metal components with desired shapes. Laser metal cutting is not merely a machining technique but also an art of transforming metal materials.

With outstanding advantages such as high productivity and exceptional cutting quality, laser cutting is not only widely adopted but also emerges as the top choice for fabricating intricate and complex metal details. Exploring the pros and cons of laser cutting on metal sheets, we can observe its effectiveness and versatility across various applications, yielding superior-quality final products.

Operating Principle

The process of laser metal cutting operates based on the following principles:

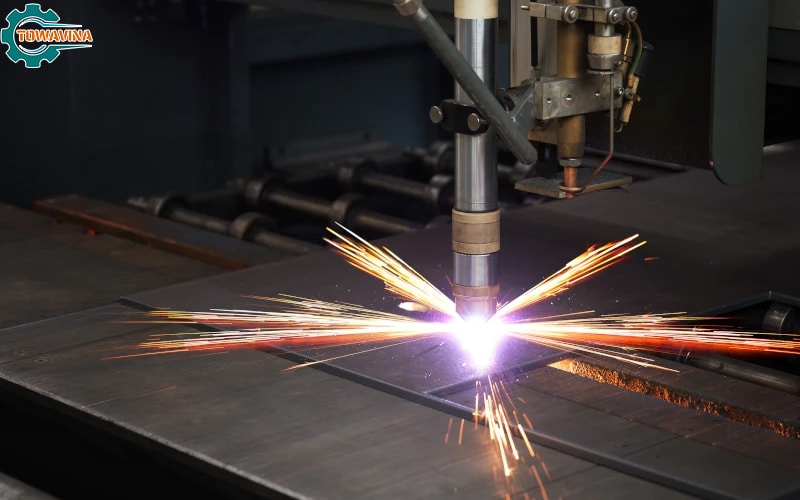

- A laser beam is emitted from a high-energy and high-temperature source. Using a system of converging lenses, the laser beam is focused and directed onto the surface of the metal workpiece.

- The concentrated laser beam induces combustion and high temperatures at the cutting location. Subsequently, a high-pressure air stream is employed to propel the molten metal away from the workpiece, creating a cut with a smooth and aesthetically pleasing surface according to specifications.

- Typically, laser cutting machines are pre-programmed, and during operation, the cutting process adheres to the pre-established drawings. This ensures the accuracy and precision of the cutting process, facilitating the production of products that align precisely with the intended design.

Characteristics of Laser Metal Cutting Method

The laser metal cutting method is recognized as one of the most modern and widespread metal processing techniques today. Below are the prominent characteristics of this method:

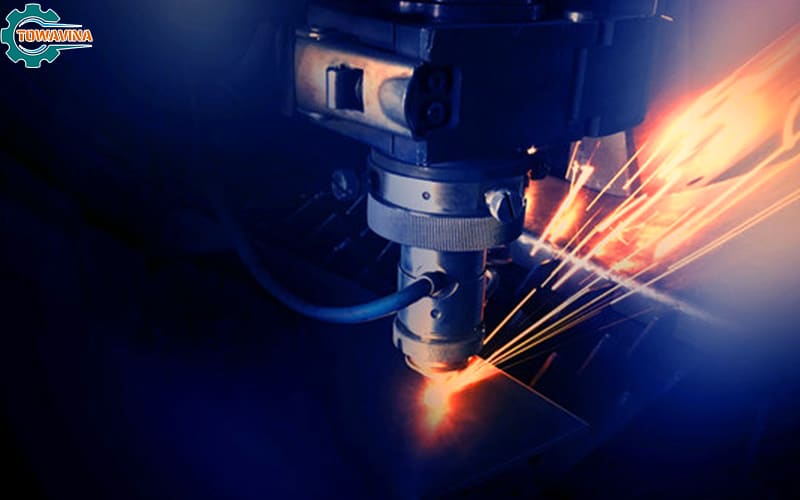

- Fast Cutting Speed: Laser cutting achieves very high cutting speeds, enhancing production efficiency.

- Versatile Metal Cutting: Laser cutting is flexible and can cut various types of metals with different thicknesses, creating different shapes, straight and curved lines as required. Particularly, it can process intricate, complex details with high precision.

- High-Quality Cutting Lines and Finished Products: Laser cutting produces smooth, small, sharp cutting lines with high precision. The aesthetic quality of the final product is also ensured. The error rate is very low, and the metal does not deform after the cutting process.

- Equipment and Technology Used: Utilizing pre-programmed CNC laser cutting machines, it operates silently, providing a serene and efficient working environment.

With these outstanding advantages, laser metal cutting is the top choice for processing various metal products.

Towavina – Leading Metal Processing Unit

In the field of providing metal processing services, Towavina Mechanical is highly regarded for the quality of its processing products, ranking among the top with excellent customer support services. When selecting a partner for metal processing, the most crucial aspect is to find units that meet criteria related to machine systems, experienced engineering teams, and high-quality after-sales services.

Towavina is not only a favored unit but also a prioritized choice, equipped with advanced and continuously updated machinery, and a team of workers and engineers trained extensively to ensure high professional expertise. At Towavina, we commit to delivering a professional service experience from accepting orders to successful delivery and inspection. Alongside laser cutting services, we also provide various other metal processing services.

If you have further questions or need additional information, feel free to contact us at Towavina. Contact us today and get a quote for CNC machining services.TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com