With the continuous development of science and technology, the mechanical engineering industry has undergone significant innovations. Currently, mechanical processing enterprises are gradually shifting towards using CNC mechanical processing machining methods instead of traditional processing methods.

However, do you wonder about the differences between CNC and traditional machining? Read our article here, where Towavina Mechanical Engineering will compare the details between these two methods and assist you in optimizing and developing your machining processes.

Overview of CNC Mechanical Processing Method

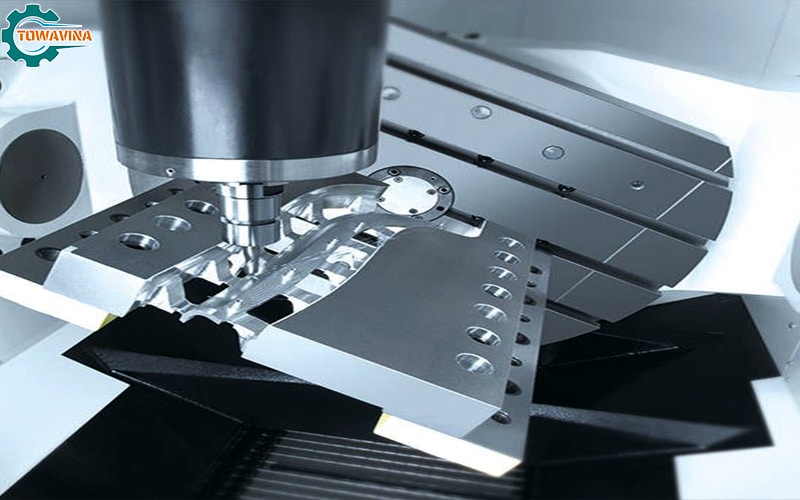

CNC machining plays a crucial role in the mechanical industry, representing a breakthrough step. Instead of relying on labor, CNC technology uses computers to control tooling devices, creating an automated and precise production process.

CNC operates based on computer programs containing specific commands and instructions for the machining process. The CNC machine’s controller converts these commands through sensors and encoders, controlling the motor and other machine parts to produce products with high accuracy and reliability.

Optimizing the production process through the integration of electronics and mechanics brings many significant advantages, including high precision, fast machining speed, the ability to reproduce accurate products, and reduced dependence on labor. The CNC system not only supports mass production but also makes on-demand production efficient, reliable, and flexible.

The CNC method is not only an elegant combination of artificial intelligence and the power of machinery but also actively contributes to the development of the modern industry and manufacturing.

Advantages of CNC Mechanical Processing Method

The high precision of CNC machining is ensured through the use of computers and sensors, allowing the machine to achieve very high accuracy, typically with errors in the range of a few micrometers. This translates to increased reliability and product quality, as errors are minimized.

Fast machining speed is one of the important advantages of CNC, as it eliminates the need for manual labor. Instead, the machine is controlled by a computer and motor, speeding up the production process and improving efficiency in machining.

The ability to produce batches is enhanced through the application of pre-programmed programs. This helps quickly and accurately produce batches of similar products while minimizing errors in the production process.

Flexibility in design is another important feature of the CNC process. Computer support allows for easy changes and adjustments to both design and programming. This creates flexibility, allowing adaptation to the specific requirements of the product and optimizing the production process.

Why Use CNC Mechanical Processing

The choice between CNC mechanical processing and traditional methods depends on the type of product as well as the specific requirements of the project, and each method brings unique advantages.

CNC mechanical processing is often preferred for its high level of automation and precision in batch production. This automation helps minimize errors, optimize production time and costs, and opens up the possibility of producing complex products that traditional methods may struggle with.

However, traditional machining still holds value in certain cases. This method is often more flexible in handling special materials and producing small quantities of products. It can also be easily adjusted to meet the specific requirements of each product, requiring fewer technical machine requirements compared to CNC machining.

The choice between these two methods often depends on the specific needs of the project as well as the production scale. The intelligent combination of modern technology and traditional techniques can maximize efficiency and product quality.

The decision on which method to use should be based on a careful consideration of factors such as the complexity of the product, production scale, and specific project requirements. This helps make the most appropriate decision, leveraging the distinctive advantages of each method to ensure efficiency and quality in the production process.

Conclusion

Above are the information and knowledge about CNC mechanical machining methods. If you have further questions or need additional information, feel free to contact us at Towavina. Contact us today and get a quote for CNC machining services.TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com