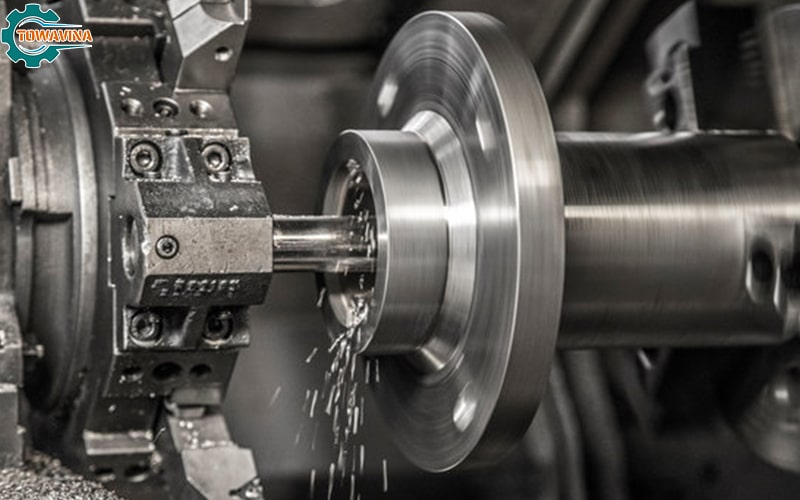

When undertaking CNC mechanical machining, optimizing costs requires careful consideration of various factors such as materials, design, finishing, quantity, and lead time. The most crucial aspect is not only the cost of materials, setup, or finishing but also the machining time.

During production, the required time will depend on the material and design, as well as technical requirements and precision of the component, directly impacting costs. Additionally, the geometry and tolerances will determine the quantity and type of necessary machinery, along with the skill level of machinists, directly influencing CNC mechanical machining costs.

Optimize the Selection of Material Types

Materials not only affect costs from raw material usage to CNC mechanical machining processes but also depend on their manufacturability. Typically, materials with lower costs are easier to machine than those with higher costs. Therefore, choosing suitable materials for CNC mechanical machining can help reduce machine time and costs, as well as the use of less expensive cutting tools. For example, using conventional steel tools instead of carbide or expensive alloys. Using hazardous materials may require additional safety measures, potentially increasing production costs.

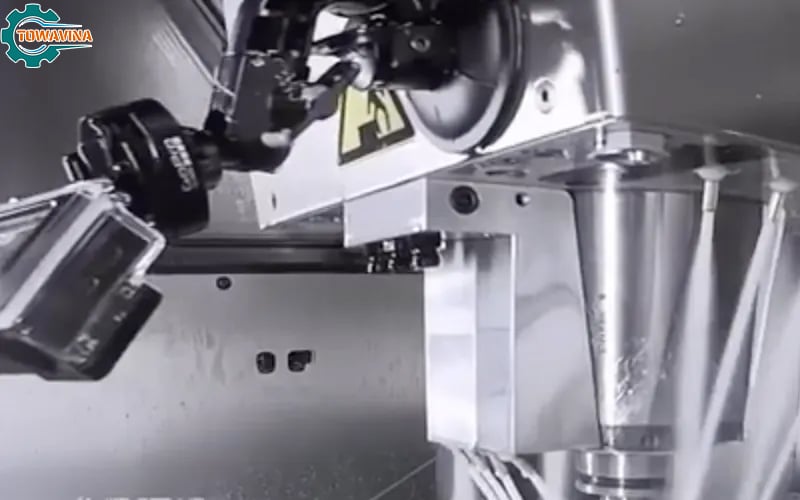

Choose the Appropriate RPM for CNC Mechanical Machining

The production of a large quantity of components on a CNC milling machine directly impacts the cost of each product. Producing more items reduces the cost per component, although the overall total cost may be higher.

Evaluate Products Carefully

The quantity of components produced on a CNC machining center directly affects the cost of each product. Producing more items helps reduce the cost per component, even though the overall total cost may be higher.

In the CNC metal machining industry, cost efficiency is often achieved when producing fewer than 10,000 components. Delivery speed also significantly impacts costs: shipping over a few weeks will be cheaper than shipping within two to three days.

Machining Complex Components

Determining the manufacturing cost depends on the size and complexity of a component. Larger components often require more materials, and complex parts involve multiple machining stages, potentially requiring the use of multiple machines and complex programming, as well as high setup costs. Complex components, such as those requiring operations on multiple surfaces, may reduce production costs if designed as independent parts and then connected after CNC mechanical machining is complete.

Minimize Cavities and Pockets Inside Components

Components designed with deep internal pockets, also known as deep pockets, are a typical example of how the geometry of a part significantly affects manufacturing costs and material usage. However, creating these designs may require many working hours to remove material around and create deep holes, resulting in material waste and difficulty in removing swarf. Additionally, creating these deep holes requires the use of long and thin cutting tools, which are prone to breakage, increasing difficulties in the manufacturing process. It is crucial to design the part length not to exceed four times its depth to minimize issues during CNC machining.

Minimize Tight Tolerances

To optimize CNC machining tool performance and design efficiency, automate the job completion process. Tools such as automatic milling cutters can create rounded inside corners, and the wider the angle, the less material needs to be removed, minimizing toolpath. Narrowing the radius angle in a ratio greater than 3:1 requires more toolpaths and the use of specialized small tools, leading to increased machining time and the need to change tooling.

To minimize machining time and the need to change tools, an approach may be to maintain the same radius for all inside corners.

Always Ensure Accuracy in CNC Mechanical Machining Using standard hole sizes and drill bit dimensions in design offers several advantages in the manufacturing process. First, adhering to these standard sizes helps reduce production costs by saving materials, labor time, and optimizing the CNC machining process. However, selecting the size and depth of tapped holes also plays a crucial role in determining the final cost. Smaller than standard tapped holes may require additional time and effort when hand tapping, leading to increased labor costs.

Conclusion

This is an overview of key considerations to reduce costs when utilizing CNC mechanical machining services that we want to share with you. In conclusion, Towavina Mechanical Engineering hopes you will be able to choose the most suitable product.

Contact us today and get a quote for CNC machining services.TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com