Choosing a mechanical processing unit is different from selecting other industrial manufacturers. In the manufacturing sector, mechanical processing involves a factory providing on-demand services to customers. They undertake the processing and production of machine components, mechanical products based on your drawings or samples, without having any ready-made products in stock. To help you envisage, here are some pointers for consideration before making your decision to place an order. If you have answers to these questions, you’ll be able to choose a suitable mechanical processing unit for your needs.

Duration of Activity in the Mechanical Processing Industry

Generally, the longer a company has been operating in the field of mechanical processing, the more professional and competitive they become in the mechanical processing service. Companies need to undergo various processing projects to handle complex component projects and materials that demand extensive knowledge. They also need to have the ability to properly address challenging and anomalous issues with mechanical components.

Equipment and Machinery

To become a professional processing unit, actual production capacity is crucial. Among the most significant factors, people, workshops, and machinery are what customers easily notice.

To meet production demands, a workshop needs to equip itself with core mechanical processing machines like CNC lathes, CNC milling machines, CNC machining centers, surface grinding machines, EDM wire cutting machines, drilling machines, water jet cutting machines… These machines are capable of performing most operations in the processing process.

Usually, more advanced processing machines (from reputable brands) have higher processing capabilities. Self-processing in the workshop allows more efficient handling of multiple processing tasks for a company rather than outsourcing for two separate jobs. This significantly saves time and effort.

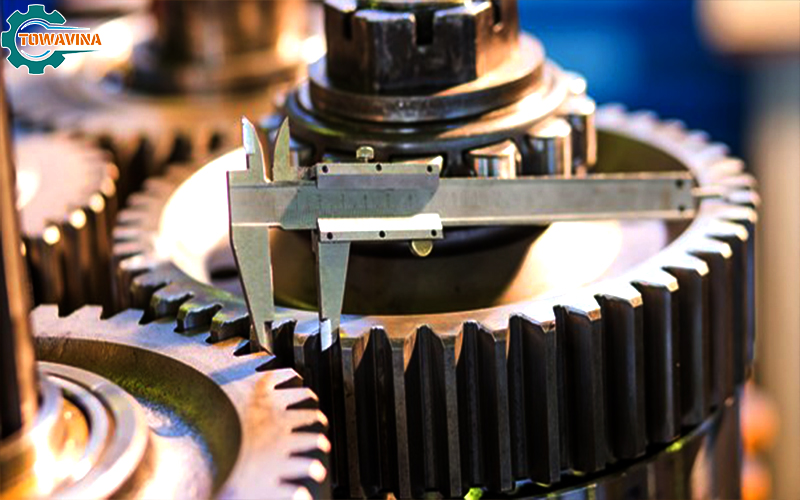

How Does the Company Control Processing Quality?

Before placing an order, you should inquire about how the unit you’re interested in controls processing quality. You need to ascertain if they use modern measuring and testing equipment.

In the mechanical processing industry, measuring and testing equipment such as Coordinate Measuring Machines (CMM), calipers, microcalipers, depth gauges, and measuring machines are mandatory.

A reputable mechanical processing unit will control quality from material inspection to checking the final finished processed components. They might also provide material reports, measurement samples, and test reports.