The machining process involves manufacturing by removing material from a workpiece to create specific components or products. This method is versatile and applicable to various types of metal and non-metal materials. One of the most common materials used in this process is aluminum.

With its lighter weight, lower hardness, and high formability, aluminum stands as an ideal material for use in machining and other manufacturing operations. Below, we’ll explore some advantages of using aluminum in mechanical processing, discuss its application in various machining processes, and describe some typical machined parts made from aluminum.

Advantages of Aluminum in Mechanical Processing

Aluminum not only offers excellent machining capabilities but is also known for several unique properties, making it an ideal material for producing high-performance parts.

Firstly, aluminum combines strength with lightweight, two crucial factors in producing parts for aerospace, space, and automotive industries.

The corrosion resistance of aluminum is also noteworthy. Aluminum alloy 6061, for instance, finds extensive use in machining industries due to its excellent corrosion resistance.

Its high conductivity makes aluminum an ideal choice for electronic components, offering better electrical conductivity than many other metals.

The flexibility of aluminum in handling and finishing surfaces opens up numerous opportunities in creating high-finished products and enhancing their functionality through processes like painting, dyeing, and anodizing.

Aluminum’s high recyclability not only minimizes waste but also creates opportunities to reuse materials from used products.

Lastly, as mentioned, aluminum is not only cheaper than many other materials but also reduces production and transportation costs due to its lightweight nature. This makes it a more economical choice while ensuring performance.

Aluminum Compared to Other Materials in Mechanical Processing

The machining process deals not only with aluminum but also various materials, from metals to plastics, paper, and wood. However, compared to other commonly used materials in machining, aluminum excels in several aspects:

Firstly, compared to steel and stainless steel, aluminum is not only much lighter but also easier to machine, facilitating the manufacturing process.

Against ABS, aluminum offers higher material durability, enhancing stability and reliability for the final product.

In contrast to PEEK, aluminum is not only easier to machine but also has a lower purchase cost, providing savings while ensuring quality.

Compared to POM, aluminum not only boasts high durability but also exhibits excellent heat resistance, making it an ideal choice in harsh conditions.

Compared to PTFE, aluminum maintains its durability and stability, making it an ideal material for applications requiring high strength and durability.

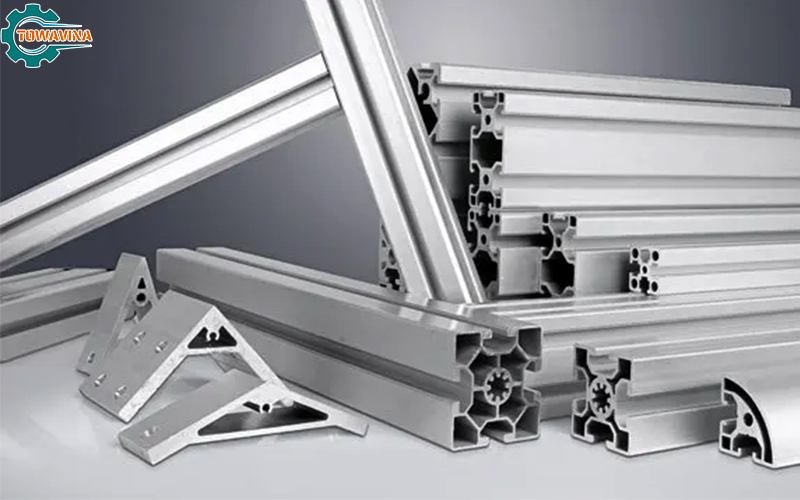

Aluminum Machining Processes in Mechanical Processing

Various machining methods such as CNC machining, Swiss screw machining, vertical/horizontal milling, and EDM have specific approaches when dealing with aluminum:

- CNC machining employs computers and compatible equipment to precisely control the motion of machine tools, producing CNC aluminum products with high accuracy and reliability.

- Swiss screw machining is suitable for small, highly precise aluminum parts, especially in the electronics and medical fields.

- Vertical or horizontal milling methods vary based on production scale: vertical milling suits small quantities of simple aluminum parts, while horizontal milling suits the production of large quantities of complex aluminum parts.

- EDM machining, although typically used for hard and challenging materials, can also be applied to aluminum and other conductive materials, using electrical discharges to remove material from the workpiece.

Each method has its advantages and specific applications in aluminum machining, resulting in final products meeting industry-specific precision and reliability requirements.

Conclusion

In the process of planning for a machining project, choosing the right material is an integral part that cannot be overlooked. For products demanding high durability, corrosion resistance, electrical conductivity, and recyclability, aluminum has proven to be an excellent choice.

If you’re preparing for the next aluminum machining project, the expert team at Towavina is ready to accompany you. We specialize in precision CNC machining for various materials, from metals to plastics and engineering materials, ensuring you receive quality products that meet your project’s requirements.

Contact us today and get a quote for CNC machining services.

TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com