Metal stamping technology is a process used to shape blanks by applying compressive force onto sheet-like materials. Different types of stamping are determined based on the temperature during the process. Interested in understanding what metal stamping technology is in the field of mechanical processing? Let’s explore this with Towavina!

Mục lục

ToggleWhat is metal stamping?

Metal stamping isn’t simply using a punch machine and a mold to shape metal sheets. It’s about leveraging the power of technology to create distinct effects or flexible changes in material shape.

The goal isn’t just about creating parts with diverse sizes and shapes, but also meeting requirements for product functionality and quality.

Metal stamping isn’t just altering the thickness of metal sheets; it’s a precise technical process to create desired shapes without changing the initial thickness of the material. This technology finds wide application in metal manufacturing to produce three-dimensional components, cuts, and meet various demands for different surface qualities.

Materials for stamping

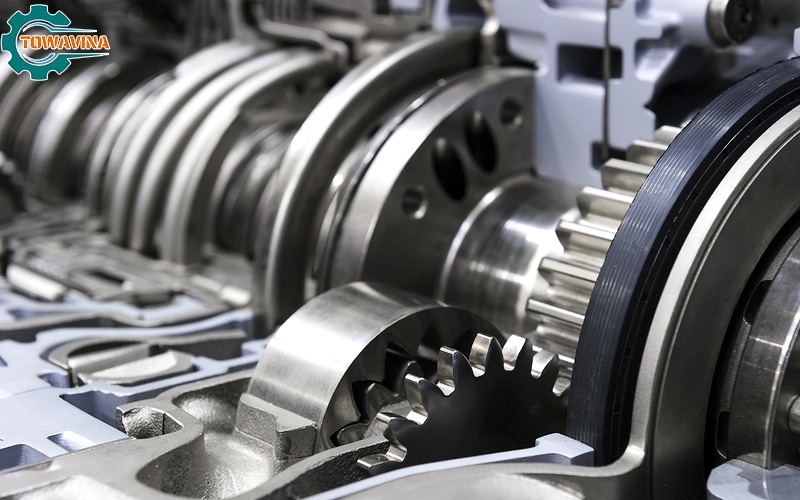

Materials for stamping Metal, in particular, stands out due to its exceptional strength. When subjected to stress, metal doesn’t merely fracture immediately like other materials such as ceramics or bricks. Instead, it flexes when it surpasses its tensile strength limit, known as its ductility.

This means each type of metal can deform uniquely. Exploiting this property, the metal stamping process creates various shapes.

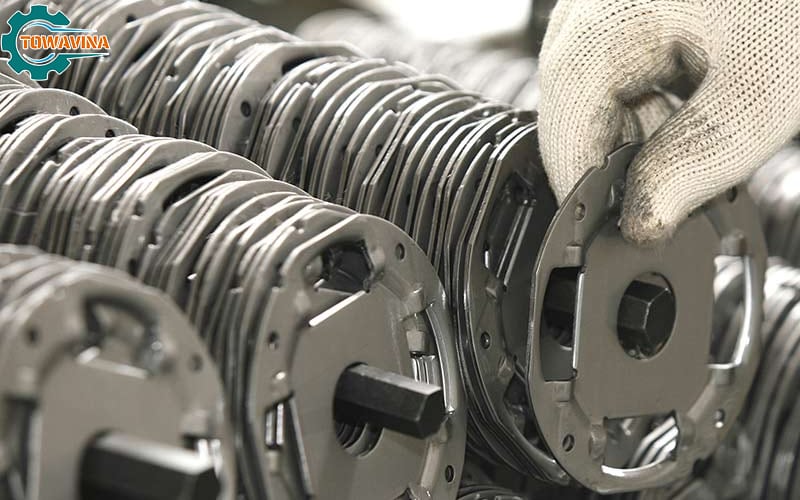

This process typically starts with creating steel molds in the desired shape, including upper and lower molds. Then, raw materials are placed between these molds and pressed shut on a stamping machine.

When pressure is applied, the molds force the material to deform according to their shape. The outcome is a meticulous process where even the strongest metals undergo changes in shape due to the substantial pressure applied by the stamping machine.

The Metal Stamping Process

The commonly used stamping process involves two primary methods: punching and bending. In punching, a metal sheet is positioned between a die and a punch. As the punch moves down into the die, it cuts the metal below it away from the original sheet. The cut-out metal parts are then collected for use or recycling, and this process is repeated until the desired shape is achieved.

In the bending process, upper and lower dies apply force to the metal sheet using spring pressure, and then a punch is used to apply pressure to the area needing bending.

Despite the seemingly straightforward nature of metal stamping technology, it encompasses various manufacturing methods. To achieve better quality, all processing methods require establishing standards and continuous improvement to enhance production efficiency and product quality.

Applications of Metal Stamping

The metal stamping process finds application across diverse industries, serving various purposes in different industrial sectors.

We observe the utilization of metalworking in agriculture, household appliance manufacturing, weaponry and ammunition production, aerospace, energy storage, construction, electronic equipment, automotive industry, outdoor sports equipment, and lighting projects.

Every industry leverages the metal stamping process to create components and products tailored to their specific needs. This involves using different metal materials and flexible machining techniques to produce reliable, high-quality products catering to the requirements of each sector.

Conclusion

This article has provided a partial overview of the metal stamping technology process. If you’re preparing for the next aluminum machining project, the expert team at Towavina is ready to accompany you. We specialize in precision CNC machining for various materials, from metals to plastics and engineering materials, ensuring you receive quality products that meet your project’s requirements.Contact us today and get a quote for CNC machining services.

TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com