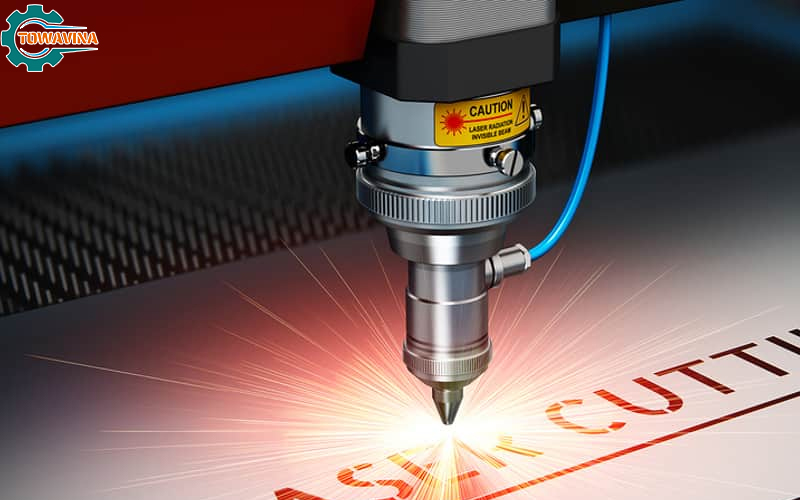

The laser cutting machine is an amazing tool capable of creating various products. From manufacturing simple boxes to engraving detailed images on wood or constructing complex three-dimensional objects. It is used to process pre-designed metal products.

However, some people still don’t quite understand how CNC laser cutting machines work and what the principle behind metal laser cutting is. Let’s explore that with Towavina in this article.

Mục lục

ToggleWhat is CNC laser cutting?

CNC laser cutting technology utilizes a laser beam to cut through different materials. The laser machine is computer-controlled, using a laser beam to accurately cut or engrave materials. The laser beam is high-amplification and high-convergence light. This laser beam causes the material to burn, melt, or vaporize locally. The cutting ability of the laser depends on the type of laser and the power of the specific machine.

CNC laser cutting technology is commonly used in industrial manufacturing but is now widely applied in schools, small businesses, and individual users.

The laser cutting process operates by adjusting the output of the high-power laser beam through optics. Laser optics and Computer Numerical Control (CNC) are used to adjust the material or the laser beam’s focus.

Commercial laser beams are used to cut materials through a motion control system following CNC or G-code of the pattern to be cut on the material. The converging laser beam is directed onto the material, causing it to melt, burn, vaporize, or be blown away by a gas jet, leaving a high-quality surface edge.

Why use lasers to cut metal materials?

Lasers have various applications. One common use is cutting metal sheets. Laser cutting on mild steel, stainless steel, and aluminum sheets provides high precision, excellent cutting quality, a very small Kerf, a small heat-affected zone, and the ability to cut complex shapes and small holes.

Most people know that “LASER” is actually an acronym for “Light Amplification by Stimulated Emission of Radiation.” Laser technology has been developed since the 1960s. However, how can light penetrate through a steel sheet?

The operating principle of a metal laser cutting machine

Involves a high-intensity beam of light, which can have a single wavelength or a specific color. For instance, in the case of a CO2 laser, the wavelength falls within the infrared range of the light spectrum, making it invisible to the human eye. The laser beam has a diameter of about 3/4 inch as it travels from the laser source through the machine’s laser delivery system. It can be reflected in various directions by mirrors or “bend mirrors” before finally being focused onto the material. The laser beam converges through the nozzle aperture before reaching the material. It also passes through a nozzle aperture that contains compressed gas, such as Oxygen or Nitrogen.

The concentration of the laser beam can be achieved through a special lens or a curved mirror, occurring within the laser cutting head. The laser beam must be precisely focused to ensure that the shape and energy density at that point are completely circular and consistent, while also being focused within the nozzle.

By concentrating energy onto a single point, the heat density at that point becomes extreme. Think of it like using a magnifying glass to focus sunlight onto a leaf and how that can cause it to burn. If you concentrate 6 KWatts of energy onto a single point, you can imagine how hot that point would become.

High power density leads to rapid heating, melting, and partial or complete vaporization of the material. When cutting mild steel, the heat from the laser beam is sufficient to initiate the typical “oxy-fuel” burning process, and the laser cutting gas will be pure oxygen, similar to oxy-fuel combustion. When cutting stainless steel or aluminum, the laser beam simply melts the material, and high-pressure nitrogen is used to blow the molten metal out of the Kerf.

On a CNC laser cutting machine, the laser cutting head moves over the metal sheet according to the shape of the desired part, thereby cutting that portion out of the sheet. The capacitance height control system maintains a very precise distance between the nozzle end and the cutting sheet. This distance is crucial as it determines the focal point’s position relative to the sheet’s surface. The cutting quality can be affected by raising or lowering the focal point from just above the sheet surface, on the surface, or just below the surface.

Numerous other parameters also influence cutting quality, but when all are properly controlled, laser cutting is a stable, reliable, and highly accurate cutting process.

In conclusion

Above is useful information about cnc laser cutting. Hope this article helps you. For detailed service inquiries, please contact us. Our team of consultants and technicians is dedicated to assisting you in achieving the desired product.

TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com