Engineer leaders are currently encountering fresh obstacles due to the continually growing global market and advancements in technology. They must find ways to ensure their existing customers remain content, cope with decreasing profit margins, and attract new customers in the face of fierce competition. Precision machining is a technology that can assist in maintaining a competitive advantage.

I. What is precision machining?

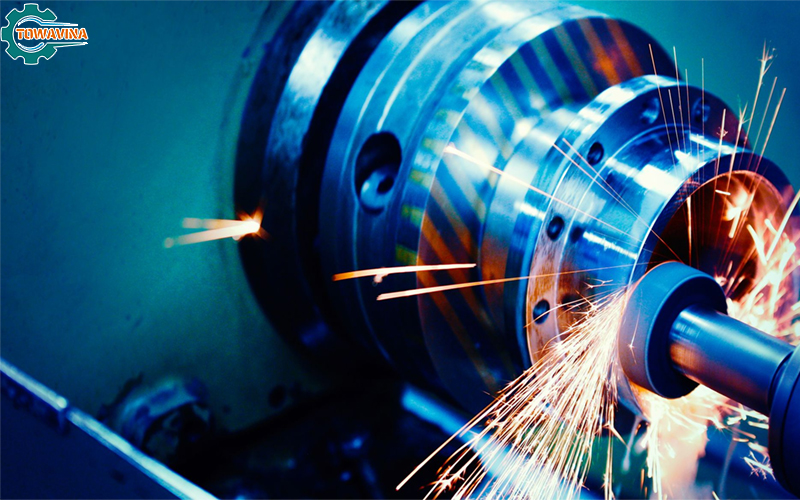

Precision machining involves the precise removal of raw material from an object to produce a smaller, finished product using cutting machines, software applications, and human engineering to meet highly specific requirements. Companies providing contract precision machining services are typically able to help with minor adjustments during the prototyping phase to comply with design and industry standards.

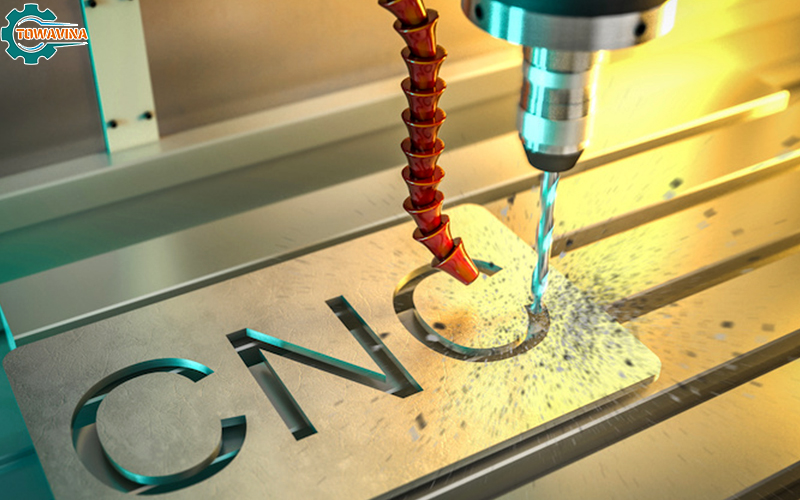

What is CNC machining technology?

CNC (Computer Numerical Control) machines are commonly used to guarantee that the final product meets precise dimensions due to the high level of accuracy required.

II. Precision machining advantages

The pace of industry today is incredibly fast. It’s crucial for your business to stay up to date or even ahead of the game in order to satisfy the needs of today’s customers.

There are 7 benefits to incorporating precision machining and outsourcing in your business model.

1. Low Error

Utilizing CNC machines allows for automated precision machining once the accurate specifications are input. The likelihood of errors is significantly reduced compared to human machining. Outsourcing this work eliminates the requirement to recruit and hire highly skilled staff to operate these machines.

2. Less Material Waste

Precision machining is centered around the concept of subtracting material, which can lead to significant material waste throughout the production process of a single product. CNC precision machining plays a crucial role in minimizing material costs by reducing human error and wastage. Additionally, contract companies often purchase materials in bulk for your job, allowing them to pass on the cost savings to you.

3. Consistent Product Quality

Precision machining using CNC machines results in consistent output every time. The ability to consistently produce high-quality product runs builds customer confidence and increases awareness of your brand.

4. Improved Workflow

When looking at how to manage opportunity costs, it’s key that engineers’ time and skills are spent on actual product development and not tiny design changes. A company that offers contract precision machining services can usually assist with minor modifications during the prototyping process to meet design and/or industry standards.

5. Reduced Turnaround Time

The opportunity exists to improve your existing factory workflow (either with in-house precision machines if you can afford the machine investment and the skilled labor to operate it), or, by using contract machining services. A contract company is experienced in this type of work and have the system in place to get the job done as efficiently as possible.

6. Faster Production Cycles

Having the ability to bring your product to market more quickly provides a competitive advantage over facilities that still rely on outdated methodologies. It also allows for greater flexibility in adapting to industry regulations or accommodating customer requests.

7. Easier Prototype Testing

Precision machining presents a chance for your business to tap into smaller specialized markets with the possibility of significant profits. Utilizing precision CNC machining enables a flexible approach to product development as the potential niche market is identified. If there is demand in the market, the machining process can transition into full-scale production. Furthermore, precision machining facilitates the creation of prototypes with functional parts, rather than just conceptual or design-based prototypes. Functional prototypes are more likely to inspire confidence in investor stakeholders compared to concept-only prototypes.

Conclusion

Towavina is dedicated to delivering high-precision mechanical components and finished products to meet diverse customer requirements. Our modern machining system enables the production of parts with exceptional accuracy. Our Precision Machining Services encompass CNC milling, CNC cutting, drilling, punching, bending, and more. We utilize cutting-edge machinery sourced from top equipment suppliers in the industry to ensure the precision and quality of our products.

Contact us today and get a quote for CNC machining services.

TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com