CNC machining services are commonly provided in specialized CNC machine shops. These shops are typically outfitted with advanced technology and provide precise CNC machining capabilities within a controlled setting.

The abundance of CNC machining suppliers has made selecting the appropriate CNC machining service a crucial decision, necessitating thorough consideration and assessment of various essential factors. Let’s dive right in the 5 factors to consider when choosing CNC machining services.

1. What type of Equipment and Tools are being used?

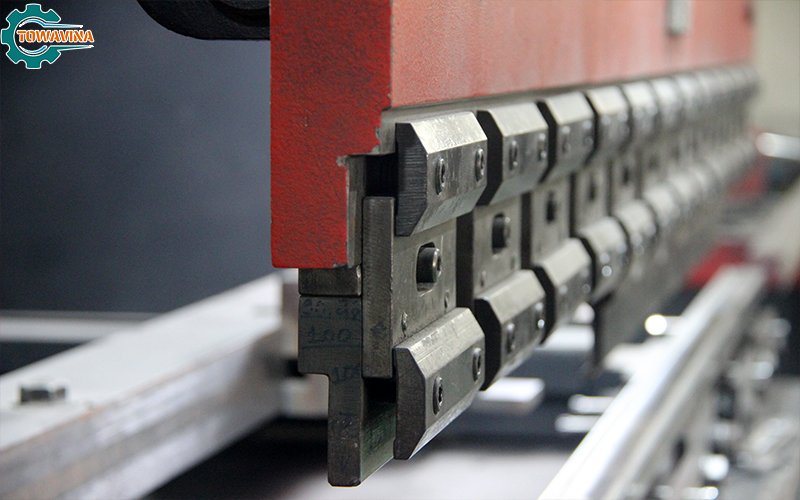

The effectiveness of a CNC machining service depends heavily on the quality and variety of tools it has available. Lathes, mills, and routers all play a crucial role in the success of a project, and the right machinery can make a significant difference. Various types of CNC machines are designed to handle different types of tasks.

A company that has a wide variety of high-tech machinery is probably able to handle a wide range of projects. The fact that they can use advanced techniques such as surface grinding also shows their dedication to providing comprehensive machining services.

2. Does the Company have substantial Experience in CNC Machining?

Experience is equivalent to expertise. CNC machining involves a precise process, and with each project, a CNC machining company gains more knowledge and skills. A seasoned service provider would have the know-how to handle various machining requirements, minimizing the likelihood of errors and ensuring a more seamless overall process.

Nevertheless, it’s important to not only focus on the duration of operation. It’s also crucial to take into account the projects that a specific CNC machine shop has undertaken and the range of clients it has catered to. This will offer a more comprehensive understanding of their level of experience and expertise.

The expertise of a service goes beyond machine operation. It encompasses their understanding of intricate designs, utilization of CAD/CAM software, and proficiency in diverse machining techniques.

3. Where is the Company Located?

The geographical location of the service provider can have a significant impact on different aspects of your project, such as shipping expenses, turnaround times, and the ability to communicate effectively.

Opting for a nearby CNC machining service can result in faster lead times and reduced shipping expenses. Nevertheless, if the international service provider presents superior skills and pricing, the extra shipping costs and time might be justifiable.

4. How do their Pricing align with your Budget?

The pricing for CNC machining services can differ significantly. It’s important to find a provider whose pricing is within your budget while still maintaining high-quality service.

Make sure to take into account any hidden expenses, including shipping and extra fees. Keep in mind that the most inexpensive choice may not always be the most suitable. Don’t sacrifice quality for cost.

5. What is the Size of the Business?

The scale of the business can reflect its ability to manage your project. While larger businesses may have greater resources, smaller ones could provide more tailored service. It’s important to consider how their size might impact your project before making a choice.

The realm of CNC machining demands precision and adaptability. The provider must be able to deliver precise outcomes, adapt their processes to accommodate modifications, and meet the specific requirements of your project.

Every company has distinct machining requirements, ranging from intricate designs to specific quantity demands. An ideal CNC machining service should be capable of addressing these individual needs by providing tailored solutions instead of generic services.

Quality control is essential in the realm of CNC machining. Seek out a service provider that has strong quality assurance measures in place.

These could involve routine inspections throughout the manufacturing process, a last-minute examination prior to shipment, and procedures to address any mistakes or flaws.

Conclusion

Selecting service goes beyond simply comparing prices. It necessitates a comprehensive assessment of numerous factors, such as the provider’s expertise, machinery, material availability, certifications, turnaround times, communication efficiency, location, and their dedication to quick prototyping and ongoing enhancement.

By thoroughly evaluating these factors, you can make a well-informed choice that meets the needs, budget, and schedule of your project, and select a CNC machining service provider capable of producing high-quality items efficiently and affordably.

It’s important to note that a strong partnership with a CNC machining service provider goes beyond addressing your immediate requirements. It also involves their capacity to accommodate your company’s future needs, grow alongside your business, and consistently enhance their services to deliver optimal outcomes.

Towavina, an ISO9001-2015 certified company, provides high-quality CNC machining services for metal materials. Our capabilities cover a wide range, from producing one-off CNC prototypes to mass production exceeding 100,000 units. We maintain tight tolerances of ±0.01 mm and ensure rapid delivery to our customers. Contact us today and get a quote for CNC machining services.

TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com