Laser cutting is a highly favored and widely used mechanical processing method in today’s market. It can cut various types of materials, from hard metals to softer non-metals. Among these, laser cutting of stainless steel is one of the common applications. Stainless Steel Laser Cutting is considered the most optimal processing method today. Let’s explore this further with Towavina in this article.

Characteristics of stainless steel

Before delving into the laser cutting method for stainless steel, it’s essential to understand what stainless steel is. Stainless steel, also known as “corrosion-resistant steel,” is an alloy primarily composed of chromium, with high oxidation resistance. Additionally, it contains other elements such as carbon, silicon, manganese, which provide effective anti-corrosive properties.

To discuss stainless steel, understanding its crucial characteristics like excellent corrosion resistance, high hardness and durability, and low reactivity is necessary. Due to these distinctive properties, stainless steel finds wide applications in various fields, including shipbuilding, interior and exterior decoration, medical equipment, signage, jewelry, and household appliances.

What does laser cutting of stainless steel involve?

Given these unique characteristics, the most efficient stainless steel processing method is of interest. Currently, there are several methods for cutting stainless steel, such as laser cutting, gas and oxy-fuel cutting, CNC machine cutting, plasma cutting, and water jet cutting. Among these, laser cutting is the most preferred method due to its high precision and cost-effectiveness compared to other methods. A key strength of this method lies in its fast cutting speed, fine and smooth cutting lines, without the need for additional product processing.

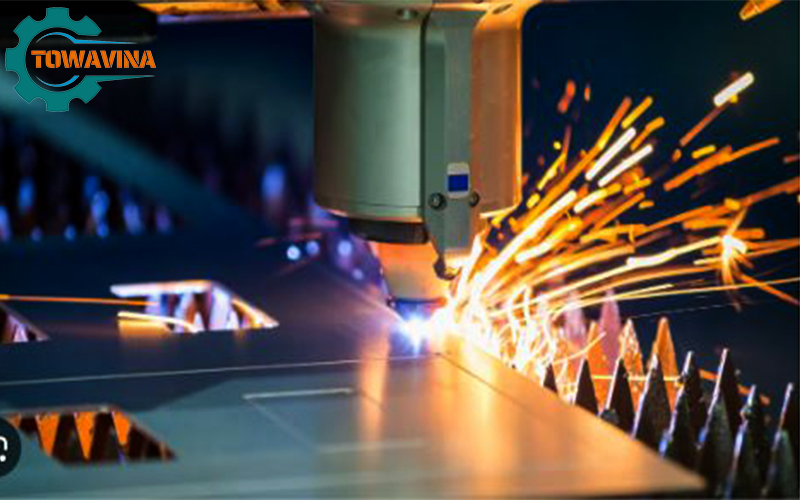

Laser cutting of stainless steel utilizes a high-energy laser beam to create smooth cuts on the surface of stainless steel. The cutting process is swift, highly precise, resulting in narrow cut grooves. This method is applicable for cutting 3mm thick stainless steel sheets, intricate machine parts, nameplates, patterned stainless steel, and various other applications. The technology enables processing along straight and curved lines, producing products with beautifully cut edges and smooth finishes.

Moreover, this method can handle intricate ornamental details efficiently, ensuring prompt completion times. Compared to other traditional methods of cutting stainless steel, laser cutting offers higher efficiency. Some products created using this method include stainless steel gates, main doors, balconies, decorative items, windows, and staircase railings.

The applications of laser cutting technology in stainless steel are diverse and significantly impact the aesthetics and functionality of various domains. Elements like table legs, chairs, beds, or cabinets contribute to accentuating the aesthetics and functionality of living and working spaces. Additionally, products like mirror frames, decorative walls, or edge borders play a crucial role in defining space and artistic highlights.

Furthermore, in the realm of construction, the application of systems like roofing, soundproofing, railings, staircases, emergency exits, gates, elevators, and house doors not only ensure sturdy structures but also guarantee safety and convenience for users.

In the supporting industrial sector, the flexibility of products such as electrical conduits, cable trays, industrial kitchen cabinets, cargo covers, water storage tanks, or systems like ventilation ducts and heat-resistant pipes holds significant importance in manufacturing and industrial management.

Utilizing materials and equipment like stainless steel drainage grates, support systems, wall-hanging racks, or various types of workbenches and sinks, industries can enhance efficiency and attain high-quality standards in the production and handling of goods.

Reliable Address for Stainless Steel Laser Cutting

Towavina takes pride in being the leading entity in stainless steel processing using laser technology, delivering reliability and optimal quality in Binh Duong. We commit to providing high-quality products at the most reasonable prices for our valued customers. With a mission to expand our manufacturing scale, we continuously strive to meet all customer needs.

Our commitments to our customers include

- Utilizing laser technology to ensure nearly perfect precision in processing all stainless steel products.

- Employing modern machinery that allows us to process various thicknesses of stainless steel sheets.

- Capable of processing a diverse range of product designs, even those with high complexity and difficulty.

- Ensuring timely delivery schedules for orders of all sizes, from small to large quantities.

- A team of highly skilled technical experts dedicated and experienced in numerous large-scale projects.

We are confident that with our professionalism and unwavering commitment to improvement, we will be the most reliable and trustworthy partner for all your stainless steel product needs. The above information shares insights into the stainless steel laser cutting method. If you have a need for stainless steel laser cutting services, please contact us for suitable and advantageous price quotations. We are delighted to serve you.