Stainless steel is a widely used material across various industries and sectors. Therefore, the process of stainless steel processing is an area of significant interest. In this article, we aim to provide a clearer understanding of this process.

1. Understanding stainless steel

1.1. What is stainless steel?

Currently, stainless steel is a widely utilized material in the market. Globally, it accounts for approximately half of the total amount of stainless steel produced and is applied in industrial sectors as well as in everyday human life. Stainless steel can be commonly found in items such as pots, pans, utensils, cutlery, tables, chairs, decorative pieces, glass door handles, staircase balusters, and much more.

1.2. Properties of stainless steel

Stainless steel is a widely used material known for its durability, high hardness, and excellent resistance capabilities. Particularly, stainless steel produces aesthetically appealing products. Below are some notable characteristics of stainless steel:

- SUS 304 stainless steel exhibits outstanding rust resistance, hence it is often used in architectural fields and food processing equipment due to its ease of cleaning. Additionally, stainless steel is employed in the textile dyeing industry.

- Stainless steel can withstand high temperatures, ranging from approximately 870 to 925 degrees Celsius. In cases demanding higher durability, stainless steel may have higher carbon content.

- Stainless steel possesses relatively weak mechanical and physical properties but can increase hardness in low-temperature environments.

- Stainless steel can be processed well, allowing shaping without the need for heat processing. This is why stainless steel is widely used in the production of stainless steel-related components.

2. Custom stainless steel processing procedure

To create perfect stainless steel products, a comprehensive processing procedure involving the following steps is necessary:

Step 1: Detailed product drawing

This is the most crucial step in the stainless steel processing process, impacting the quality and production efficiency. The individual involved in creating the processing drawing must possess experience and understanding of the product. The tasks in this step include:

- Gathering information from the client regarding the shape, size, function, and initial drawing of the product.

- Redrawing the overall shape of the product.

- Executing stainless steel processing based on the drawing: cutting, bending, welding, and assembling the product.

- Monitoring the process for adjustments in case of any arising errors.

Step 2: Cutting stainless steel according to detailed drawing

To achieve precise stainless steel cutting according to detailed drawings, it requires accuracy and diligence from the craftsmen. Given the high cost of stainless steel, mistakes could lead to substantial losses for businesses. Accurate cutting of stainless steel components expedites and enhances the installation process significantly.

To attain accuracy in cutting stainless steel, various machines can be employed:

- Laser cutting machine: Used for cutting curved lines.

- Hydraulic cutting machine: Used for cutting straight lines.

- Angle cutting machine: Utilized for cutting angles according to the bending shape.

- Punching machine: Employed for creating holes in stainless steel products.

- Hydraulic bending machine: Used for bending stainless steel as per the drawing.

Step 3: Installation and fixation of the product

Installation and fixation require craftsmen capable of comprehending the drawing details, knowing the suitable sequence for assembling components to ensure correct installation and completion of all product details.

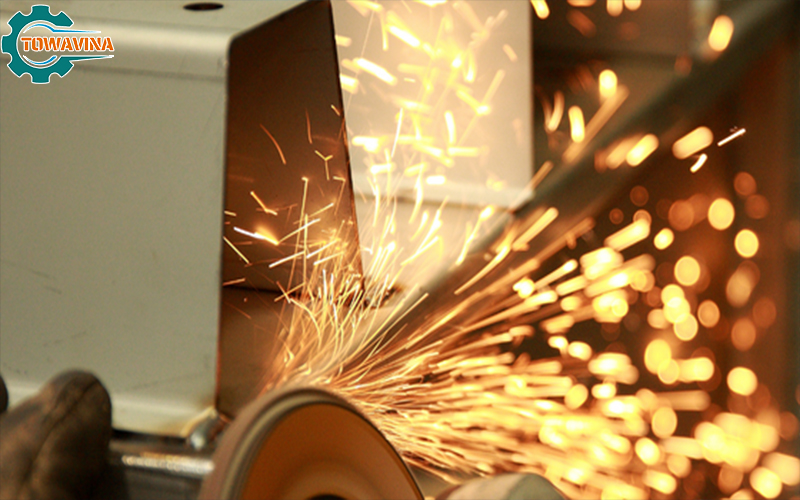

Step 4: Grinding, polishing, and removing weld marks

This task demands experienced craftsmen who adhere to all stainless steel processing procedures. Initially, flat grinding of all weld marks is done using a 120-grit sanding wheel. Next, the weld marks are re-ground using a 240-grit sanding wheel. Finally, a soft sanding wheel is used for a smooth surface. For larger quantities, industrial grinding machines can be utilized.

Step 5: Cleaning, inspection, and packaging

Stainless steel can be cleaned using soap, kerosene, starch powder, or talcum powder to achieve a bright and shiny finish. Inspection is crucial to ensure the quality and uniformity of the stainless steel product. First, check the dimensions, design, and quantity of completed products. Then, inspect the materials and ensure the welds are secure. Finally, assess the aesthetic aspects and address weld marks for colored stainless steel products.

3. Conclusion

This article from Towavina aims to introduce you to the stainless steel processing procedure. We hope this information has been beneficial to you. For detailed service inquiries, please contact us. Our team of consultants and technicians is dedicated to assisting you in achieving the desired product.

TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com