Before engaging in mechanical processing, it’s crucial to carefully examine the following details to ensure the quality and performance of the product achieve the best results. Follow this article to grasp these essential considerations before embarking on mechanical processing.

1, Define Processing Requirements

To initiate a mechanical processing project, it’s essential to comprehend the specific project requirements. Analyze technical drawings and specifications to understand the technical requirements and characteristics thoroughly. Simultaneously, communicate with the customer or requester to clarify information and specific demands. Understanding the processing requirements is a fundamental basis for determining suitable methods and procedures.

2, Select Suitable Materials

To ensure the properties and performance of the final product, choosing appropriate materials is vital. Factors such as hardness, durability, heat resistance, and corrosion resistance need evaluation to select the suitable material type. Research the features and properties of each material type, considering their processing capabilities and alignment with project requirements.

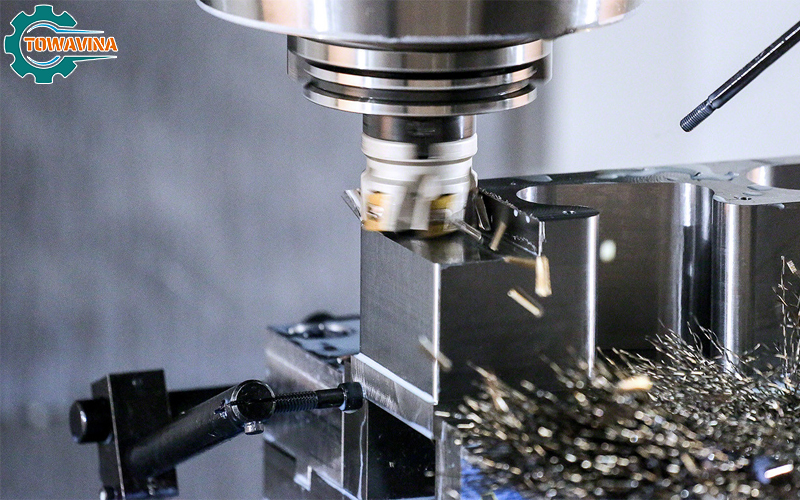

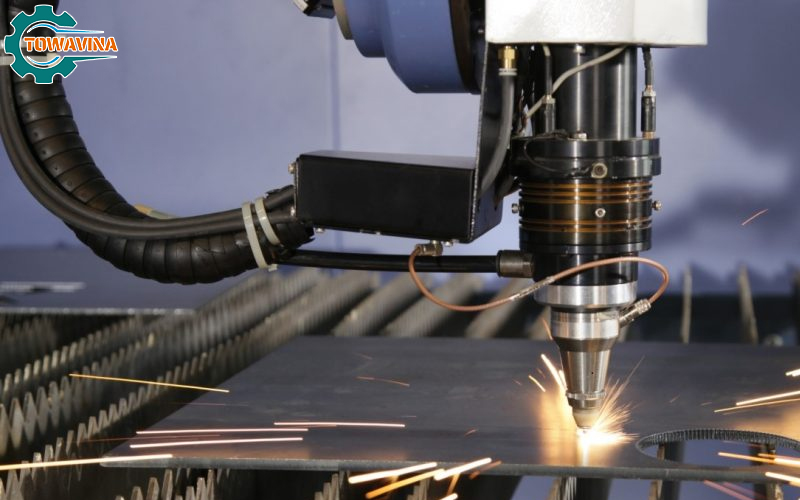

3, Determine Processing Methods

Choosing the appropriate processing method is a pivotal factor that determines the success of a mechanical processing project. Evaluate common processing methods such as turning, milling, grinding, or CNC machining to determine the method that aligns with the project’s requirements and characteristics. Consider factors like precision, processing time, and costs to make the final decision.

4, Prepare Tools and Equipment

To execute the mechanical processing procedure effectively, it’s crucial to prepare the correct tools and equipment. Identify suitable tools and equipment for each processing stage and ensure their proper inspection, maintenance, and calibration. Additionally, ensure safety in using tools and equipment to prevent accidents and create a safe working environment for employees.

5, Quality Management

Quality management is a crucial part of the mechanical production process. Establish a quality control system to ensure each processing step meets the technical standards. Conduct product quality checks and assessments to identify and rectify errors and issues. Simultaneously, address arising problems and improve the production process to guarantee the quality of the final product.”

6, Machine Inspection and Maintenance

Machinery plays a crucial role in the mechanical processing process. Regular inspections and maintenance of machinery are necessary to ensure stable operation and achieve the highest performance. Training and guiding staff in proper and safe machine operation optimize production and prevent unwanted incidents.

7, The Selection Of a Suitable Mechanical Processing Company

To succeed in mechanical processing projects, it’s crucial to pay attention to choosing the right outsourcing partners. Choose suppliers with good quality and experience, ensuring they meet project requirements and minimize risks during processing. Additionally, consistently focus on enhancing the skills and knowledge of the workforce in the field of mechanical processing. Train and educate employees to improve skills, enhance work processes, and ensure safety during processing.

Ultimately, implementing these considerations before mechanical processing not only ensures the quality and performance of the final product but also reduces costs and enhances competitiveness for the business. Therefore, invest time and resources in executing the mechanical processing procedure accurately and efficiently.

Towavina is one of the enterprises capable of high-quality machine part manufacturing at reasonable costs. We produce components, parts, machinery spare parts, and industrial products, including medical equipment, with optimal quality and cost-efficiency.

Conclusion

The considerations before mechanical processing play a vital role in ensuring the quality and performance of the final product. For detailed service inquiries, please contact us. Our team of consultants and technicians is dedicated to assisting you in achieving the desired product.

TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com