Currently, metal stamping technology is widely employed in manufacturing metal products. This technology enables businesses to produce large quantities of metal products in a short amount of time, surpassing other metal processing methods available in the market. Let’s explore this further with Towavina in this article.

Mục lục

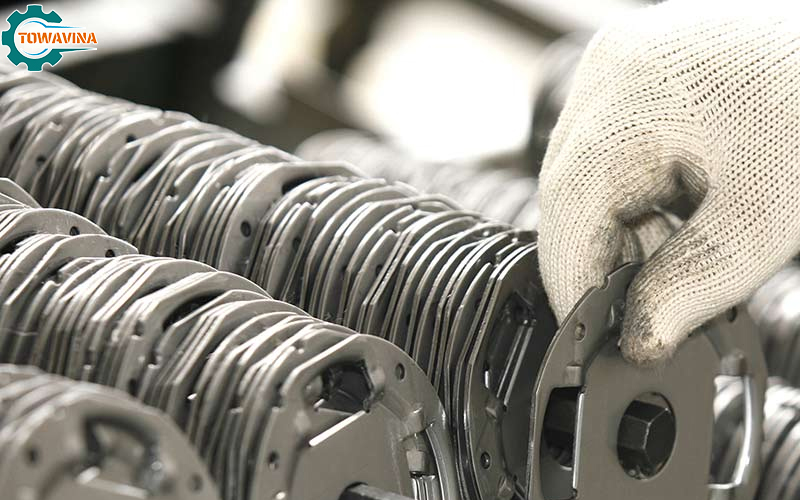

Toggle1. Metal stamping concept

The concept of metal stamping involves a technique used to process perforations on thin materials such as large metal sheets, paper, leather, and more. Therefore, this method finds extensive application in fields like packaging, medical, pharmaceuticals, and beyond.

With stamping techniques, multiple round perforations can be created in a single strike. This has significantly enhanced operational efficiency for businesses. To augment operational capabilities, many stamping machines now integrate CNC technology to automate parts of the stamping process. Consequently, businesses can save costs and time spent on manual labor. Simultaneously, the quality of stamping is improved with absolute precision.

2. Introduction to stamping dies

Stamping dies are tools used to shape products during processing. They are employed on thin metal sheets, alloys in their hot or cold state. Under pressure, products are shaped based on pre-existing designs. Typically, stamping dies consist of two main parts: the anvil and the hammer. The hammer, attached to the die, moves to apply pressure onto the blank.

3. Mechanism of mechanical stamping machines

The core design principle involves converting circular motion into linear motion. This component is controlled by a gearwheel. Subsequently, the control of the gearwheel’s operation, camshaft, connecting rod through a clutch, generates the linear motion of the slide.

Furthermore, the transition between linear and circular motion between the connecting rod and the slide will require a transmission point. This design comprises two structural types: cylindrical and spherical. Through this axis, circular motion is transformed into linear motion of the slide.

4. Classifications of Stamping Machines

4.1. Hydraulic Stamping Machines

Hydraulic stamping machines, also known as hydraulic cold stamping machines, utilize a hydraulic system to exert pressure onto the surface of the material. Their operation is based on Pascal’s principle. These machines use hydraulic cylinders to generate tremendous pressure, equivalent to employing a mechanical lever. Therefore, hydraulic press machines can effectively process thick metal sheets.

4.2. Angle Cutting Stamping Machines

Angle cutting stamping machines use hydraulic stamping force to impact materials. When employing this type of machine, businesses might require manual labor for some manual operations during the angle cutting process. Presently, these machines are widely used for cutting steel tubes, iron tubes, aluminum alloys, and bending metal material angles.

4.3. Pneumatic Stamping Machines

Pneumatic stamping machines combine compressed air and hydraulics, exerting strong stamping force during processing. They find extensive use in industries requiring high output capacity such as pressing, shaping, cutting, stamping, and riveting.

4.4. Compound Stamping Machines

Compound stamping machines, also known as progressive stamping machines, continuously carry out the entire process of stamping metal parts based on the pre-existing design. Simultaneously, these machines remove excess material from the workpiece. With their continuous stamping capability, compound stamping machines are used for products requiring large quantities of parts in a single processing run.

5. Applications of Metal Stamping Processing

Currently, the primary application of stamping technology is the processing and shaping of thin metal sheets and alloys. It is used to create perforations of various sizes and can remove excess material from metal blanks.

Moreover, stamping processing technology is also applied to materials such as leather, paper, ensuring efficient and stable work performance across all materials.

6. Reliable Metal Stamping Service in Binh Duong

Towavina is currently one of the most reputable metal stamping service providers in Binh Duong. The company is renowned as a leader in the field of metal stamping processing in Binh Duong. They efficiently process various material blanks, ensuring consistent quality for each product. Additionally, equipped with modern machinery, Towavina can handle large production volumes according to customer requirements and is ready to provide services when needed. For further details, please contact us:

TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com