In our modern world, intricate technology continuously advances at a staggering pace, enveloping our surroundings. The intricate gears and components nestled within machinery in our daily lives provoke curiosity about their creation process. The backbone behind the majority of these products and their manufacturing lies in one common solution – CNC precision machining.

Pioneering modern industries, computer numerical control (CNC) techniques automate the production of parts at astounding speeds. Taking this innovation further, CNC precision machining refines the process, enhancing precision and streamlining manufacturing.

This piece will delve into precision machining, its methodologies, required tools, and various related aspects.

What is Precision Machining?

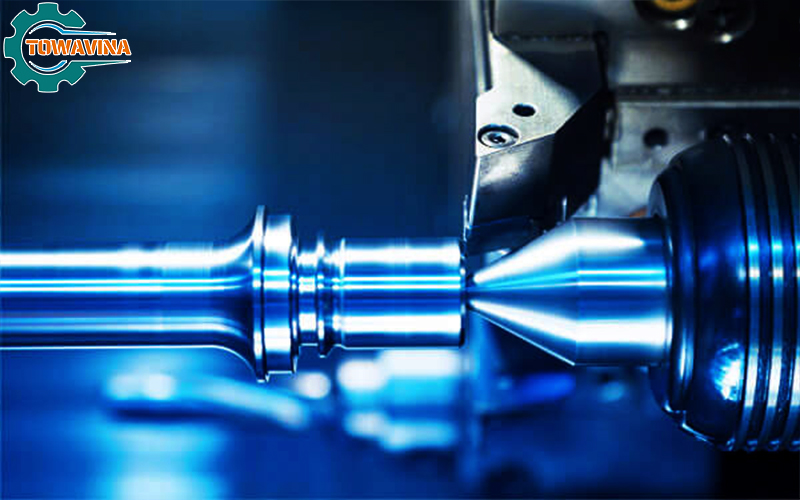

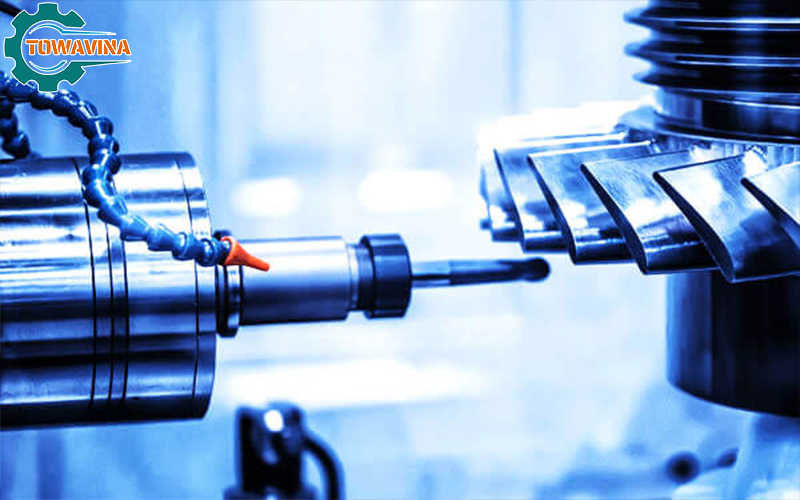

Precision machining stands as an advanced method employing computer-guided machinery to craft intricate parts. This precise and swift process caters to the creation of components demanding exacting specifications or intricate designs. Skilled operators or automated high-speed robotics often oversee this meticulous task.

Operating through subtractive manufacturing principles, the process commences with a solid block, sculpting it into the desired form with precision tools. Its widespread application involves crafting diverse components that seamlessly integrate into complex systems.

The success of precision machining hinges on a dual synergy:

- Firstly, the process necessitates top-tier cutting tools adept at delicately shaping materials to match exact product dimensions. Secondly, the pivotal role of a Computer Numerical Control (CNC) machine cannot be overstated. Harnessing high-speed robotics, this machine orchestrates the cutting tool’s movements across the workpiece, dictating precise cuts and milling actions.

- Secondly, the pivotal role of a Computer Numerical Control (CNC) machine cannot be overstated. Harnessing high-speed robotics, this machine orchestrates the cutting tool’s movements across the workpiece, dictating precise cuts and milling actions..

What are the Steps in the Precision Machining Process?

Precision machining companies typically follow a standardized sequence of procedures when crafting diverse parts.

- Graphical Model Design To initiate the manufacturing process, a graphical model becomes a prerequisite. Utilizing Computer-Aided Design (CAD) software, designers fashion 2D and 3D representations of the desired parts. Often, initial concepts stem from hand-drawn sketches, serving as blueprints for the CAD designer to meticulously craft accurate dimensional models. CAD software options vary widely, encompassing both free and paid versions. Alternatively, manufacturers might opt to outsource complex design tasks.

- CAD to CAM Conversion While Computer-Aided Design generates a comprehensible digital rendition of the part, CNC machines—integral to part production—cannot interpret this format directly. CNC machines operate based on coordinates for tool movement and workpiece manipulation. Consequently, the design must be transformed into a format that imparts precise manufacturing instructions. Computer-Aided Manufacturing (CAM) software bridges this gap by converting the CAD model into a CAM format understood by CNC machines.

- Within Computer-Aided Manufacturing (CAM) software, two code types—G and M codes—play pivotal roles. G codes regulate cutting tool coordinates, dictating movement, while M codes manage auxiliary machine functions, such as activating or deactivating coolant flow.

- Machine Setup With designs translated into CAM format, the next step involves machine setup. This phase encompasses crucial tasks like calibrating machine tools and securing the workpiece onto the machine. Machine tools employed can vary depending on the material and final part design, with an array of precision machining tools serving distinct purposes. Attention to detail is paramount here—ensuring proper clamping and validating machine parameters like coolant levels are within optimal ranges.

- Execution of Machining With the setup finalized, the machine program stands poised for execution. Most CNC machines feature displays enabling real-time monitoring and parameter adjustments. Upon program initiation, the CNC machine initiates the precision machining process.

- Completion Upon completion of the precision machining process, the manufactured part is ready for extraction. Depending on specifications, the part might undergo secondary processes such as grinding or polishing. Nonetheless, in many instances, products crafted through precision machining exhibit a finished state that obviates the necessity for additional processing.

What are the Applications of Precision Machining?

Precision CNC machining serves as the cornerstone of numerous industries, playing a pivotal role in tooling and final product creation. Its applications span various sectors, including:

- Prototyping: Across diverse industries, precision machining is indispensable for crafting prototypes. These prototypes necessitate precise replication of intended designs to showcase product features accurately. Precision machining stands as the optimal method to meet these exacting requirements.

- Automotive Industry: Within the automotive sector, precision CNC machining plays a crucial role. It contributes significantly to the manufacturing of vehicle components, ranging from intricate engine parts to precise chassis elements, ensuring high performance and reliability in automobiles.

- The automotive sector relies on precision machining to craft intricate gears, engine components, axles, and various nuts essential for vehicles across the spectrum, from two-wheelers to ships and airplanes.

- In the medical industry, where technology is increasingly sophisticated, precision machining plays a pivotal role. From automated surgical tools to intricate equipment, the demand for micro-level precision in machining is met through advanced precision techniques.

- Aerospace, known for its cutting-edge technology and stringent material requirements, heavily depends on precision machining. This industry necessitates not just accuracy but also the ability to work on incredibly hard materials. Precision machining offers a versatile solution for aerospace needs, catering to prototypes and full-scale parts alike.

- Similarly, the defense sector mirrors aerospace requirements, demanding rugged materials and top-tier precision machining. It encompasses a broad range of applications, from prototyping new weaponry to developing complete missile systems.

Conclusion

Absolutely, precision machining indeed offers exceptional value without sacrificing dimensional accuracy, making it the preferred choice for manufacturing prototypes or producing parts at scale. This process ensures high-quality outcomes consistently.

For reliable precision machining services, consider reaching out to Towavina. We specialize in this field and guarantee a quote within 24 hours, providing a swift and efficient solution for your machining needs. For detailed service inquiries, please contact us. Our team of consultants and technicians is dedicated to assisting you in achieving the desired product.

TOWAVINA CO.,LTD

Binh Chuan 44, Binh Chuan, Thuan An, Binh Duong

Hottline: 0979.034.634 – 0931.155.155

Mail: sales@towavina.com

Website: towavina.com